I. Industry status and needs

Intelligent power station is based on automation, using the technology of the Internet of Things and equipment monitoring technology to strengthen information management and services; clearly grasp the power generation process, improve the controllability of the power generation process, reduce manual intervention, timely and correctly collect the data of the power generation process, so as to scientifically formulate the power generation plan, and to build a highly efficient and energy-saving, green, environmentally friendly, and comfortable environment of humanized factories. Intelligent power plant applies VR, big data, personnel positioning, etc. to the industrial field, which facilitates the monitoring of the site, accident forecasting and diagnosis, realizes the leap from digitalization to intelligence, changes the previous operation and management mode, and realizes the process from manual decision-making to machine-like decision-making.

Intelligent power station management system and safety system, the use of advanced Internet of Things, the Internet, artificial intelligence and other advanced technologies, to achieve the equipment layer, control layer, production supervision layer of the state of the supervision level data collection and data at all levels into the central core management, to achieve the ultimate goal of intelligent power plant production coordination. Intelligent power plant currently exists in the following application requirements and industry pain points:

Pain point 1 The daily inspection work of the staff in the production area is relatively backward in management, and the traditional inspection is to make records and control by manual registration at the inspection points manually. Inspection information can not be shared in real time to the department, the management can not grasp the inspection status in real time, there are cases of missed inspection.

Pain point 2 Production area staff on duty can not be quickly assessed, the traditional attendance is carried out by swiping the card, can not effectively monitor and statistics on duty data, personnel distribution and so on.

Pain point 3 The power station will carry out planned maintenance work for the units, which requires a large number of outsourced personnel to carry out operations such as cleaning, earth moving, maintenance, etc. The lack of effective supervision and statistical means for the safety control and time attendance of the outsourced personnel is a major safety hazard and the lack of accurate statistical data.

Pain point 4 At present, all kinds of power station supervision and monitoring systems are relatively independent, such as video monitoring system, personnel management system, production management system, access control system, etc., and the information is formed into silos, which can't provide emergency management platform and comprehensive decision-making support for managers at all levels, and the management efficiency is low.

Hainan Shidian has launched a program based on the application difficulties and pain points of smart power stations.UWB wireless positioning technologyAccurately locate the position of power station personnel to ensure that the behavior of on-site personnel is controllable and the position is visible. Combined with positioning base station, positioning tag and other equipment to provide global location display, real-time track tracking, historical data playback and positioning monitoring and analysis, etc., it supports the rapid setting of electronic fence for accident-prone areas, and sends out local and remote warning prompts to the personnel approaching or entering the dangerous area.

II. Overall programmatic structure

The system includes UWB tag, UWB outdoor base station, positioning engine software (C/S architecture) and positioning application system. Positioning tags and positioning base station communicate through UWB pulse signals. The positioning base station transmits the received data from positioning tags to LS1000 positioning engine through 5G network and wired Ethernet for data analysis and processing, and transmits the processed accurate position to the upper layer application through an open API interface.

The system components are as follows:

- UWB tags: card-type and wristband-type, fixed on top of the person or object to be located, can periodically transmit UWB signals with tag ID information.

- UWB Indoor Ceiling Base Station: communicates with the positioning tags and transmits information back to the positioning engine algorithm software;

- Positioning engine algorithm software: locally deployed, the underlying information data is collected and processed through the algorithm of the positioning engine to get the accurate coordinates of the positioning tag.

- Positioning application software: locally deployed or cloud deployed, the application layer software realizes the basic functions such as positioning display, track playback and other functions, as well as the business functions such as electronic fence, intelligent inspection, attendance statistics and video linkage based on the expansion of location data.

Contacts

III. System hardware

IV. Programmatic functions

|

function point |

Functional Description |

|

Real-time positioning of personnel |

Realize real-time positioning management for hydropower station operators and inspectors, view the real-time location and distribution area of the located personnel, and master the personnel dynamics anytime, anywhere, with positioning accuracy of 0.3~0.8 meters. |

|

Historical track search |

The visualized traceability of overhaul operations can be achieved by playing back historical trajectories and organically combining spatio-temporal information with operational content and video images. |

|

roll call |

It is possible to get information about the activities of all the people on duty in the area by specifying the area. |

|

Call for help at the touch of a button |

The card has a built-in SOS button, long press 3S system platform sound and light alarm. |

|

electric fence |

Based on the overhaul tasks, set up virtual job fences to supervise the scope of the overhauler's work and the time of the work. Associate the tasks of maintenance personnel with time and space. Set alarm fences for the charged operation area during maintenance, and generate alarm messages on the supervision platform once non-authorized personnel intrude into the area. |

|

Inspection Management |

Draw circular, polygonal, and rectangular fenced areas, configure basic information about the inspection area, inspection schedule, and create reports through drawing tools. |

|

Failure to report activities to the police at the required time |

The range of activity of the person wearing the tag serving a sentence at a certain time, once the person is found to be out of the designated area for a certain period of time, an alarm message is sent. |

|

Alarm for entering restricted area |

Restrict the activity/access area according to the role type, unauthorized personnel entering will send out an alarm, when entering/exiting certain gates, you can set up the passing conditions, when not meeting the requirements of the personnel entering/exiting the gates will send out an alarm message; or certain areas can be entered/exited only at specific times, if entering at other times will be regarded as trespassing, and an alarm will be sent out as well. |

|

Hold-up Alarm |

An alarm message is sent when a person serving a sentence does not leave the activity area in time for a certain period of time. |

|

Alarm handling |

For non-compliance, the platform will send an alert message to keep the tags worn by personnel vibrating for proactive reminders. At the same time, the platform will also push information to the safety supervisors for on-site emergency response. For violations, real-time accurate location information is used to correlate the calling of cameras for photo forensics. In the event of an accident requiring emergency assistance, on-site personnel can also initiate a distress message to the platform by triggering the SOS button attached to the tag. |

|

on-the-job attendance |

According to the set operation attendance area, it automatically counts the time, number of people on duty and working hours of power plant operators, third party personnel and inspection personnel. The management can quickly check the on-duty situation, and the monthly statistics of working hours can also be directly based on the platform data as an audit reference for attendance. |

|

video link |

Combining the UWB positioning system with the prison video surveillance system, once a warning occurs in a certain area, such as strangers appearing at entrances and exits, personnel entering the area without authority, personnel approaching the source of danger, and personnel asking for help, etc., the system will immediately pop up the on-site monitoring screen and take pictures to record the on-site situation, which will provide the basis for efficient decision-making. |

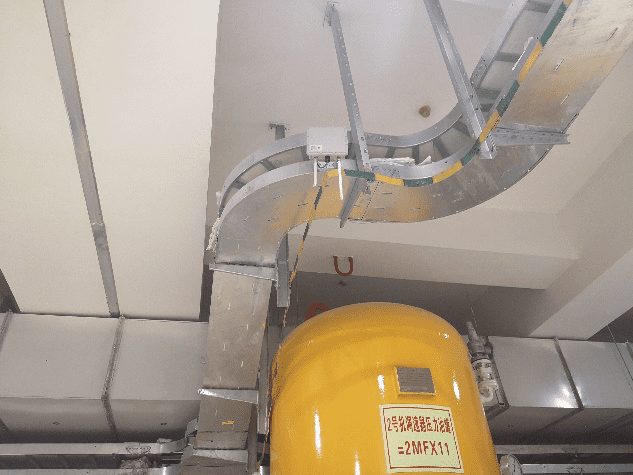

V Physical photographs of on-site installation

Content review.

Electronic tag 433MHz wireless reader WE-RW02

Electronic tag 433MHz wireless reader WE-RW02