summarize

If inside the IoT world there is notransducers, what would the Internet of Things be? The answer is: nothing. Sensors are the foundation of the IoT ecosystem, as the only functional device for data collection, and as the basic core component of information technology, the collected data is the "blood" that flows through the entire sensing, transmission and processing information system. Providing devices with the ability to collect the data used to make things happen, IoT sensors are the hardware that detects changes in the environment and collects data. They are part of the IoT ecosystem that connects the digital and physical worlds.

Temperature is the most used sensor in our daily life and work process. Temperature sensors are used to measure the heat generated by an area or object, detect changes in temperature and convert the results into data. Temperature sensors are used in a variety of industries including manufacturing, healthcare and agriculture.

Sensor Classification

Temperature sensors exist in a variety of types, sizes and shapes. There are two main classifications: contact sensors and non-contact sensors.

Contact sensors are a group of sensors that detect the temperature of an object by direct contact with it. They can be used to detect liquids, solids or gases in a variety of temperature ranges. These include thermocouples and thermistors. Thermocouples are usually inexpensive because of their simple modeling and basic materials. Another common type is the thermistor. In thermistors, the resistance decreases as the temperature increases.

Non-contact sensors do not come into contact with objects. Therefore, they utilize radiation from a heat source to measure temperature. One of the most common types is the infrared (IR) sensor.IR remotely detects the energy of an object and sends a signal to an electronic circuit, which senses the temperature of the object through a specific calibration chart.

thermistor

Thermistors or simply thermistors are special sensors because their physical appearance changes with temperature. Thermistors are made of a ceramic material, such as an oxide of a specific metal covered with glass. Thermistors have a positive temperature coefficient. They are introduced as Positive Temperature Coefficient (PTC) Thermistors and their resistance increases with increasing temperature.

Resistance Temperature Detector

RTD (Resistance Temperature Detector) A resistance temperature detector is a sensor whose resistance changes with temperature. The resistance increases as the temperature of the sensor increases. Made of a precisely conductive metal, such as platinum covered in a coil (the most common and most common RTD is 100 ohm platinum with a temperature coefficient of 0.00385), the RTD is a passive device. It does not generate its own output. External electronics are used to measure the resistance of the sensor by passing a small current through the sensor to produce a voltage. Measurement currents are typically 1 mA or less, up to 5 mA, with no risk of self-heating.

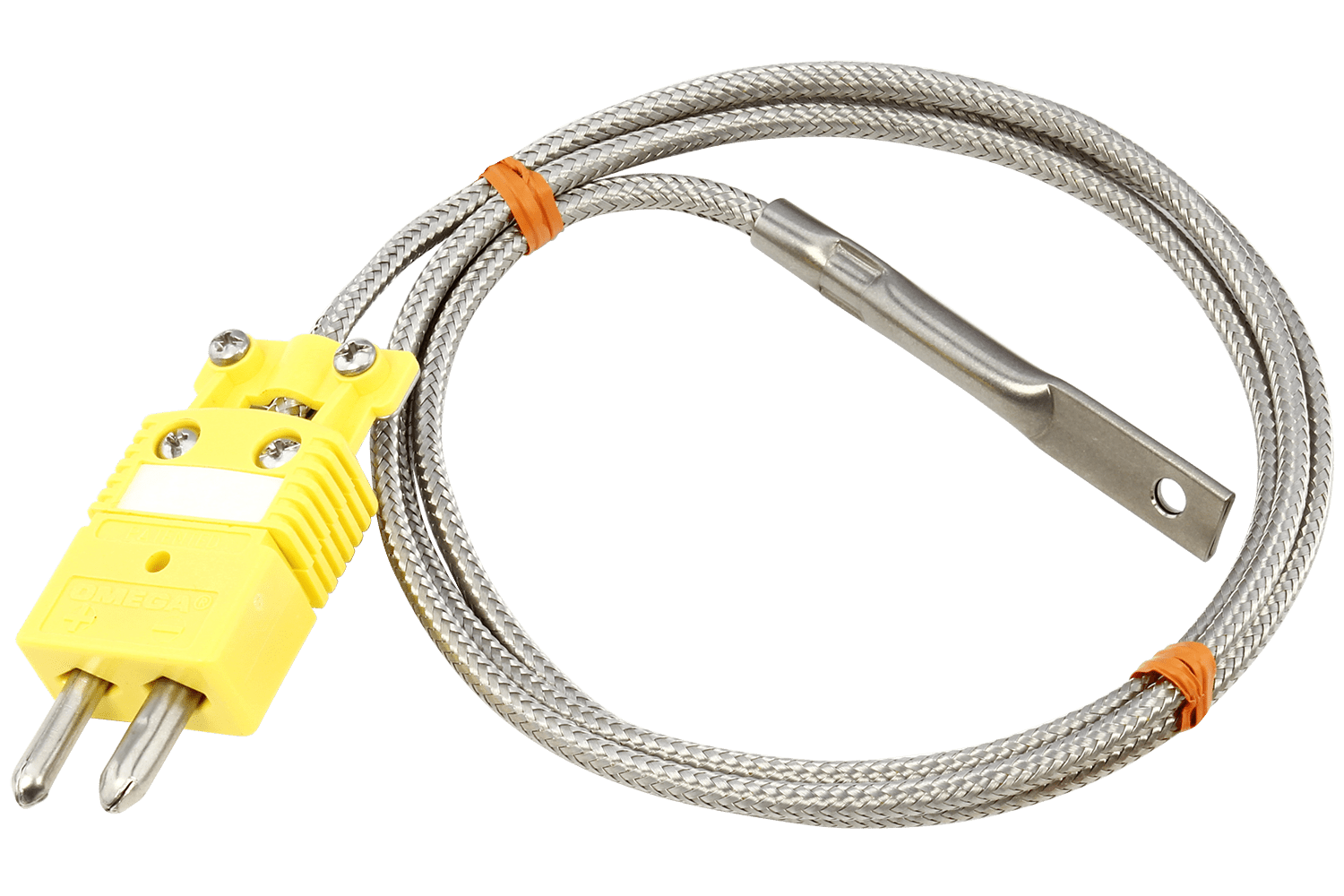

thermocouples

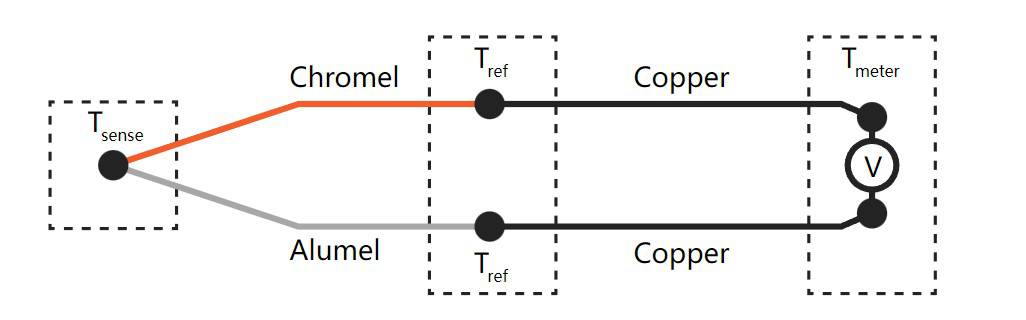

Thermocouple (Thermocouples) typically consists of two different sections of metal, such as conchoidal and copper, joined together by soldering. One section is introduced as the cold end, with a specific temperature, and the other section is introduced as the hot end, for measuring processes. Thermocouples are based on the Seebeck effect, which means that when a pair of dissimilar metals in contact with each other at both ends are subjected to a temperature change, they produce a small voltage potential. Thermocouples are the most popular sensors for temperature measurement; although not as accurate and stable as RTDs, they have a wide range of applications based on their wide temperature range, accuracy, sensitivity, reliability and simplicity.

In 1794 the Italian scientist Alessandro Volta (we'll name him "Volt") discovered: take a bare copper wire and hold your hand over one end of it. Motivated by the heat of your skin, electrons will propagate from the area where you are touching it to the cooler end away from you, creating a temperature gradient along the length of the wire. The German physicist Thomas Johann Seebeck rediscovered it in 1821. He observed that when wires made of two different metals were joined at the ends, and there was a temperature difference between those ends, a small voltage potential was created at the junction. This potential is known as Seebeck's voltage, and the generation of this potential from heat is known as the "Seebeck effect".

Negative Temperature Coefficient (NTC) Thermistors

NTC( Negative Temperature Coefficient) is a special type of thermistor that essentially responds directly to temperature changes. The negative coefficient means that the thermistor exhibits a large resistance at low temperatures. Therefore, as the temperature increases, the resistance immediately begins to decrease

Even small temperature changes can be accurately detected by negative temperature coefficient thermistors based on their large resistance change per degree Celsius. However, due to their exponential principle of operation, they require linearization. They typically operate between -50 and 250 °C.

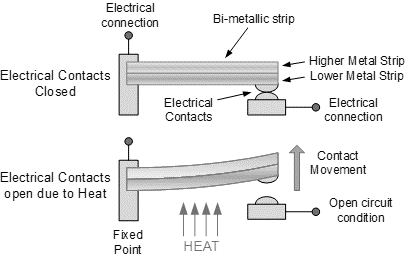

thermostat

Thermostats are contact sensors containing a bimetallic part made of two different metals such as aluminum, nickel, tungsten or copper. The main principle of thermostats is based on the difference in the linear expansion coefficients of the metals. As a result, it forces them into mechanical movement due to rising heat. Bimetallic devices can be used as electrical switches or as a mechanical method of working as electrical switches in thermostat monitoring. They are used to control heating elements in furnaces, hot water storage sources, boilers and vehicle radiator cooling systems

Semiconductor Temperature Sensors

Semiconductors consist of different types such as current output, digital output, voltage output, resistance output silicon and diode temperature sensors. New semiconductor temperature sensors offer high accuracy. The main advantage of digital temperature sensors is their precise output temperature range. The sensor output is balanced. This does not require other devices such as analog-to-digital converters. As a result, it is easier to use than thermistors that display a nonlinear resistance-temperature graph. These sensors share many common characteristics - linear output, relatively small size, limited temperature range (typical values of -40 to +120°C), low cost, high accuracy after calibration but poor interchangeability

Ordinary semiconductor diodes can be used as temperature sensors. Diodes are the lowest cost temperature sensors and can produce satisfactory results if you are prepared to perform a two-point calibration and provide a steady excitation current. Almost any silicon diode will do. The forward bias voltage on a diode has a temperature coefficient of about 2.3mV/°C and is reasonably linear. The measurement circuit is simple

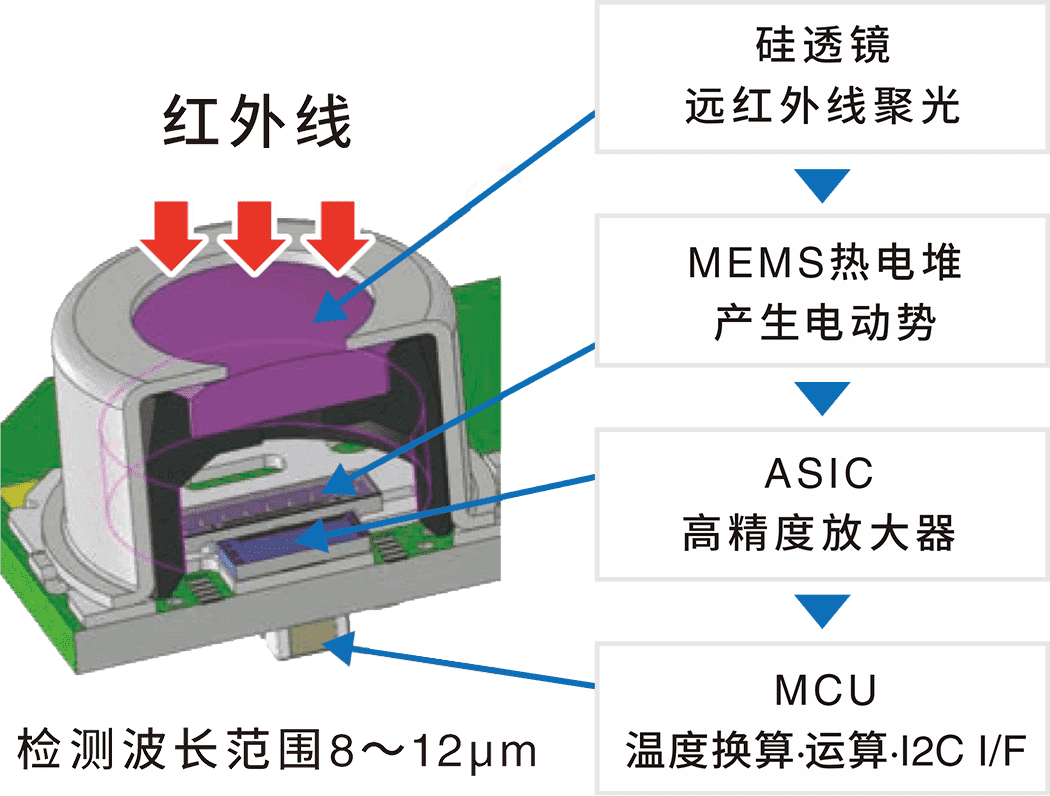

MEMS non-contact temperature sensors

MEMS non-contact temperature sensors (infrared sensors) are sensors that detect the surface temperature of an object in a non-contact manner by receiving infrared thermal energy from the object by a thermopile element, and receiving the weak thermal energy of infrared rays and outputting a signal.

We develop modules based on the MEMS sensors of our agent brand OMRON for quick use by our customers.

Sensor Manufacturers

Due to the product characteristics of temperature sensors, there are a variety of brands on the market, which can be said to be countless and diverse. Only a brief list of some of the brands of manufacturers to choose from!

- Texas Instruments Incorporated (TI) (USA)

- Hokuriku Japan (HDK)

- Japan (Omron) Omron

- STMicroelectronics (Italy)

- Germany (Baumer) Baumer

- United States (TYCO) Tyco

- Cologne, Germany (KROHNE)

- American (banner) Bonner

- Switzerland (ABB)

- Germany (IFM) IFM

- Germany (SIKA) SIKA

- Germany (SIEMENS) Siemens

- Honeywell, USA

- Germany (JUMO)

- United States (OMEGA)

- Wuhan Huadong Technology (HGTECH)

- Chongqing Chuan Yi

- Anhui Tiankang

- Gansu Tianshui Huatian

Related resources

Content review.