NB-IOT Wireless Geomagnetic Microwave Dual Mode Parking Sensor Battery Powered WE-NBGSLi-MW

Product Features

¥500

Product Overview

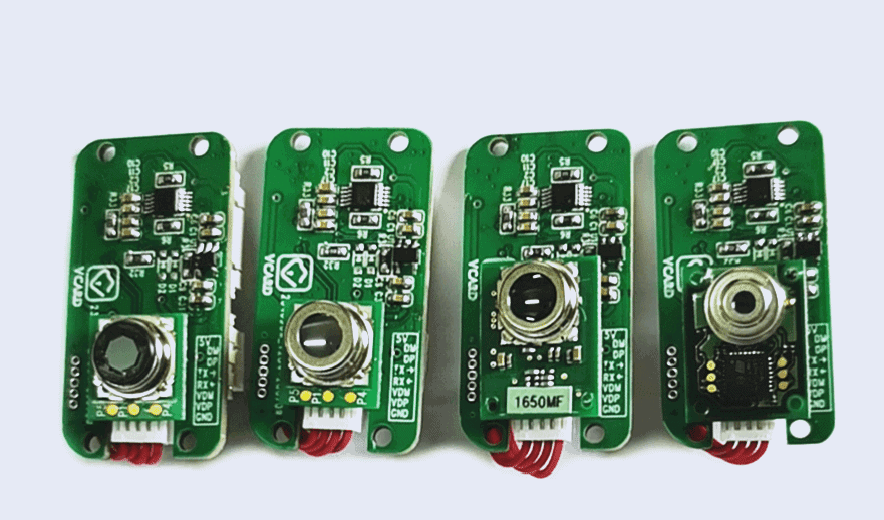

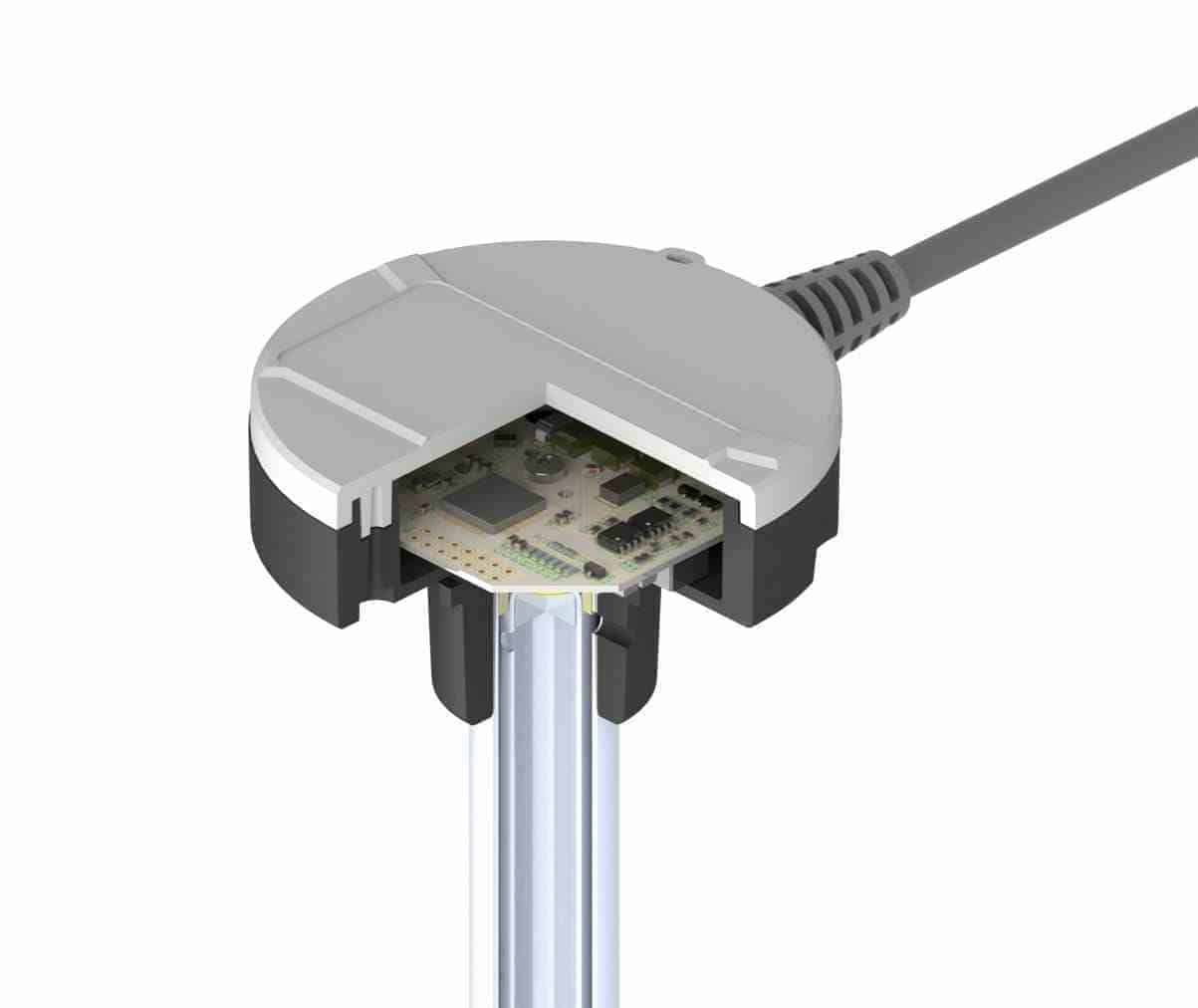

WE-NBGSLi-MW wireless geomagnetic parking space detector is the use of high-resolution magnetoresistive chip, accurate detection of vehicles on the earth's magnetic field perturbation; in order to eliminate the impact of underground pipe networks and other earth's magnetic field, the detector increased microwave radar identification, effectively increasing the detection accuracy of the detector.

This series of wireless geomagnetic parking space detector provides NB-IOT wireless communication. Using battery power supply, it is characterized by easy installation, long battery life, high detection accuracy and stable work.

Working Principle

The parking space detector is installed in the parking space, installed in the way of open hole buried in the ground, the detector real-time detection of the amount of geomagnetic changes, after many hardware filtering and digital filtering, recognized by the microprocessor algorithm; at the same time, with low-power radar technology, efficient and accurate detection of parking space vehicle parking situation.

The detector detects the change of parking space and connects to the monitoring center through NB-IOT wireless communication. The detector supports setting the timed reporting interval. When there is no change in the parking space, the device sends alarm information at the timed alarm interval. When there is a change in the status of the parking space, the device sends the report information. The report contains information about the parking space status, battery level and so on.

summarize

The Internet of Things (IoT) is formed by three aspects: the perception layer, the transmission layer and the application layer, of which the perception layer is the sensors and controllers at the basic level, which is the key link to the success of every IoT system.

Sensors, also known as transducers, are perceptual devices whose task is to detect events or changes in their surroundings and convert these physical phenomena (e.g., temperature, humidity, light, vibration, motion, PH), etc., into outputtable signals that can then be interpreted in a meaningful way. On the other hand, a controller can be viewed as a tool that functions in the opposite way to a sensor; by interpreting the signals emitted from a control system and converting them into mechanical movements, the controller actually changes its physical environment through a variety of simple actions including, but not limited to, emitting sounds, emitting different colors of light, opening and closing valves, altering the position or angle of other devices, activating them, and so on.

Common Sensors

Sensor is an independent product, can also be signed into the device, the World Power's sensors are based on a variety of communication protocols, according to different scenarios will be the integration of communication methods and sensors, the formation of wireless sensors, to facilitate the user to quickly build the embodiment of the Internet of Things, the implementation of the collection of information; according to the actual needs of a variety of environments, we can be simple and roughly divided into the following categories of sensors

temperature sensor

The most basic sensors, used in various types of Internet of Things systems, tracking the environmental temperature, equipment temperature, control temperature is one of the most basic signal source; temperature sensors can be divided into contact and non-contact measurement mode; to material to be categorized can be divided into RTDs and thermocouples of two categories; temperature sensors output signal mode can be broadly divided into three categories: digital temperature sensors, logic output temperature sensor, analog temperature sensor

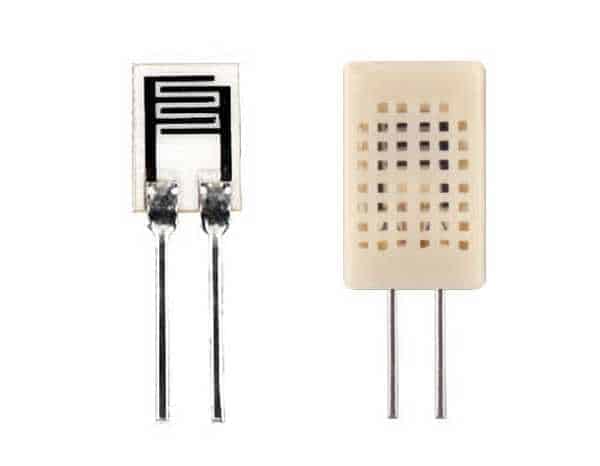

Humidity Sensor

Humidity sensors measure the amount of water vapor in the air or other gases. Typically in the industrial and residential sectors of heating, ventilation and air conditioning (HVAC) systems, hospitals and weather stations, have informed and predicted the weather. With the sensing principle to categorize can be divided into resistance and capacitance; resistance of the resistance and resistivity; capacitance of the polymer material of the dielectric constant and the capacitance value of the change in the humidity detected. Global brands of humidity sensors: Amphenol, Tyco Electronics, Honeywell, Centurion, Texas Instruments, Osun Electronics, TDK, Nippon SHINYEI, STMicroelectronics, Bosch, Alps Alpine, CoreTech

optical sensor

Optical sensors are optical signals into electrical signals, the most common optical sensors are photoelectric scattering, reflection, and through the beam; according to the different changes in the state of electrical properties can be divided into photoelectric effect 1, based on the external photoelectric effect of the photoelectric elements have phototubes, photomultipliers; 2, based on the photoconductive effect of the photoelectric elements have photoresistors, phototransistors; 3, based on the photogenerated voltaic effect of the photoelectric components are photocells and photodiodes, transistors; 4, pyroelectric sensors; global brands of optical sensors are AMS AG, Avago Technologies Inc., Sharp Corporation, Stmicroelectronics NV, Vishay Intertechnology, Elan Microelectronic Corp., Everlight Electronics Co., Maxim, Samsung Electronics, Sitronix, ROHM, ADI, Molex, Monnit, Kingbright, Silicon Laboratories, Innovacom

Acoustic Noise Sensor

Sound noise sensor is a device or equipment to convert mechanical vibration propagated in gas, liquid or solid medium into an electrical signal; divided into resistance conversion type, piezoelectric, capacitive, moving coil type; global sound sensor suppliers are: TDK, Honeywell, Panasonic, Kyocera, Teledyne, CTS, Rakon, SENSeOR, Knowles, Raltron, Vectron.

Presence of proximity sensors

Presence and proximity sensors (proximity switches) are sensors used to determine whether an object is present within a certain range, and can convert the movement and presence information of the detected object into an electrical signal. There are several common types of proximity switches: capacitive proximity switches, inductive proximity switches, photoelectric proximity switches, ultrasonic proximity switches, and fiber optic proximity switches. Global brand suppliers are: AMS AG, Allegro Microsystems, Honeywell International, Infineon Technologies AG, MTS Systems Corporation, Panasonic Corporation, Qualcomm Technologies, Renishaw PLC, Stmicroelectronics NV, TE Connectivity Ltd, Vishay Intertechnology

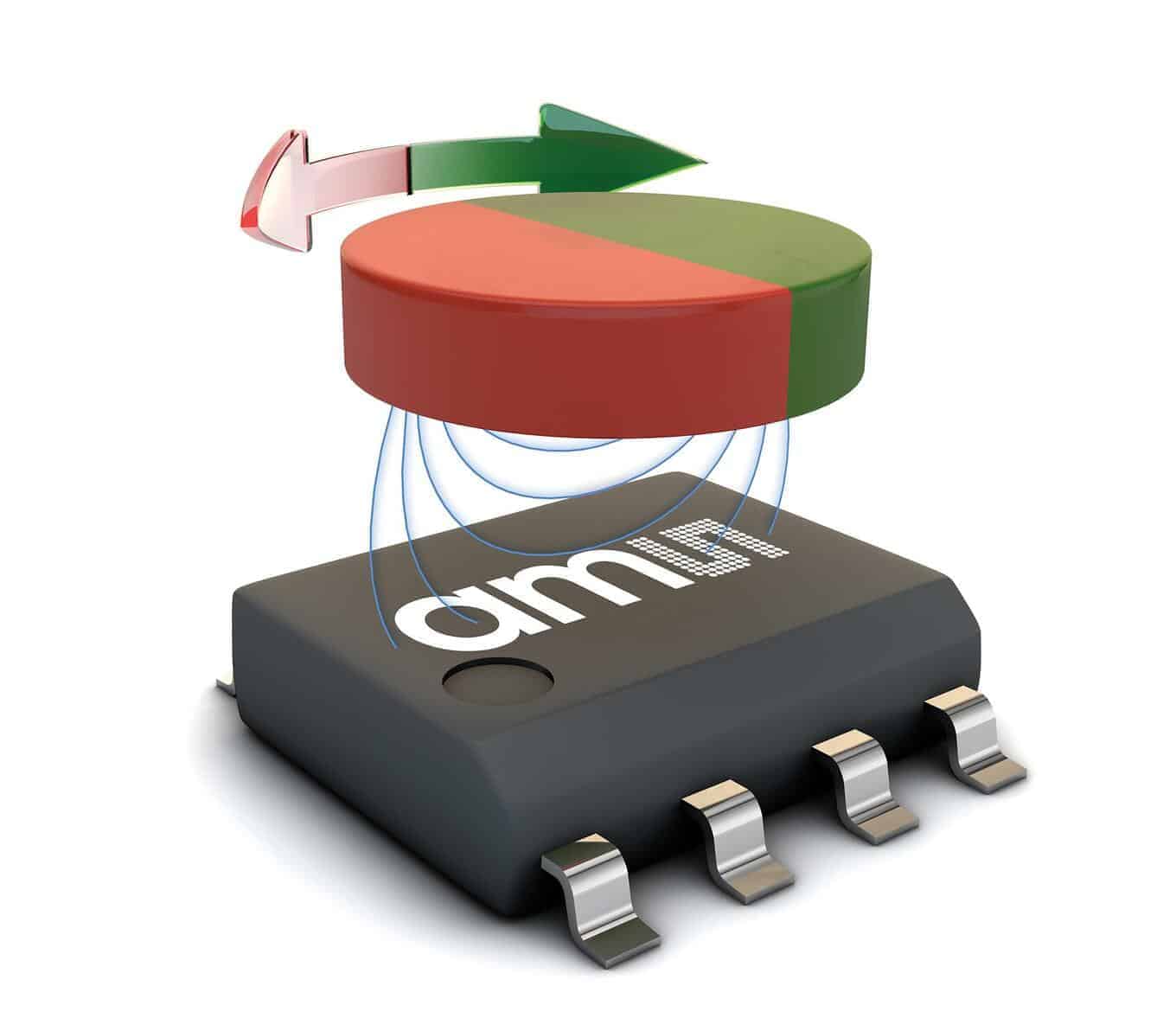

Motion Sensors

Motion sensors are sensors used to detect the presence or changing state of an object; these include accelerometer sensors, gyroscope sensors, magnetometer sensors, combination sensors, and other products; major manufacturers include Teledyne Marine, DP Marine, Sea and Land Technologies, and Sonartronic, Kongsberg Maritime, Norwegian Subsea, Ajax Systems, Nedcon Maritime, Survitec Group, Grafinta, Nautikaris, Inertial Labs, Odom Hydrographic Systems, and others. Inertial Labs, Odom Hydrographic Systems

Chemical sensors

An electrochemical sensor is a sensor that senses and detects a chemical quantity of a substance to be measured based on the electrochemical properties of the substance to be measured and converts the chemical quantity of the substance to be measured into an electrical quantity, and operates by reacting with the gas to be measured in a 100-point reaction and generating an electrical signal that is directly proportional to the concentration of the gas. According to the output signal, it can be categorized into potential sensor, current sensor and conductivity sensor. According to the substance detected by the sensor, it can be categorized into ion sensor, gas sensor and biosensor. The main manufacturers in the world are: City Technology, Alphasense, Membrapor AG, SGX Sensortech, Figaro, Draeger, Winsen, Dart, GE, Emerson.

image sensor

Image sensors are one of the most common and important sensors used today. Cell phones are the largest application market for CMOS sensors, and new applications such as automotive and security are also growing at a high rate; according to the type of scene is divided into: Distance Linear Image Sensor, Distance Area Image Sensor; global production brands are: Sony, Samsung, OmniVision, Hamamatsu Photonics, Canon, ON Semiconductor, Toshiba, STMicroelectronics, Nikon, PixelPlus, Pixart, SiliconFile, GalaxyCore, MURATA, TDK, MORGAN, TAIYO YUDEN, KYOCERA, CeramTec.

Liquid Level Sensor

A device used to monitor, maintain and measure the level of liquids (and sometimes solids). Once the level is detected, the sensor converts the sensed data into an electrical signal; level measurement can be categorized as either continuous or point level measurement. Continuous level sensors are used to accurately measure liquid levels. And point level sensors are used to determine whether the liquid level is high or low. The main types of liquid level sensors are ultrasonic level sensors, capacitive level sensors, photoelectric level sensors, microwave optical sensors and so on. The major global brand suppliers are ABB, Siemens, Emerson Electric, Schneider Electric, Texas Instruments, TE Connectivity, First Sensor, Honeywell International, AMETEK, Vega Grieshber, KROHNE Messtechnik, Fortive Corporation, Nohken, Inc, Yokogawa Electric, OMEGA Engineering, Pepperl+Fuchs, Endress+Hauser and others. n

Common Controllers

Controllers also become actuators, can be an independent product, can also be signed into the device, Seiden's controllers are also based on a variety of communication protocols, according to the needs of different scenarios, the integration of communication modes and controllers, the formation of wireless controllers (actuators); to facilitate the user to quickly build the system, the need to change the state of the device to control and perform a certain type of operation, simply divided into the following categories

Relay Controller

Relay: As noted in a change in the input (can be electrical or non-electrical) to switch the actuator appliances. Among them, used in power systems to automate the control process, and provide some protection is called control relay. According to the input and output signals are distinguished as follows: ① voltage relay: it is monitored when the circuit reaches the set value, in order to turn on or cut off the control circuit (or send out acoustic, electric, optical signals). ② current relay: monitor the current signal in the circuit, according to the rectified current action. ③ intermediate relay: essentially its coil for the voltage action type. When working between an appliance and the controlled appliance to increase the number of contacts of the former appliance or expand its contact capacity or change the contact operating state: normally closed for normally open. ④ time relay: after receiving the electric action signal, through the electromagnetic mechanism, clock mechanism mechanical mechanism or electronic circuit, make its contact act after a certain period of time, in order to realize the control system of timing control. ⑤ Thermal overload relay: It is essentially a kind of current relay. It works on the basis of thermal effect of current. (6) Temperature relay: accepts temperature as a signal and outputs a power signal. (7) photoelectric relay: accept a particular light source for the action signal, the output is an electrical signal. ⑧ other physical relays: such as pressure relays, flow relays, level relays, speed relays, gas relays, reclosing relays, etc., are to accept a particular physical quantity, the loss of a piece of electrical signal.

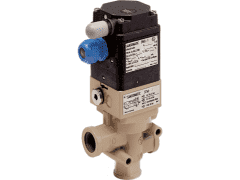

Solenoid Valve Controller

Electromagnetic valve (Electromagnetic valve) is an industrial equipment controlled by electromagnetism, is used to control the fluid automation basic components, belongs to the actuator, and is not limited to hydraulic, pneumatic. Used in industrial control systems to adjust the direction, flow, speed and other parameters of the medium. Solenoid valves can be used with different circuits to achieve the desired control, while the precision and flexibility of control can be guaranteed. There are many kinds of solenoid valves, different solenoid valves play a role in different positions of the control system, the most commonly used are check valves, safety valves, directional control valves, speed regulating valves and so on. Solenoid valve has a closed cavity, in different locations open holes, each hole connected to a different oil pipe, cavity in the middle of the piston, on both sides of the two solenoids, which side of the magnet coil is energized valve body will be attracted to which side, through the control of the valve body to open or close the movement of the different drain holes, and the inlet holes are always open, the hydraulic oil will be entered into the different drain, and then through the pressure of the oil to promote the piston cylinder, the piston and drive the piston rod, the most commonly used directional control valves, speed control valves, etc.. The piston drives the piston rod, and the piston rod drives the mechanical device. In this way, through the control of the electromagnet current breakage will control the mechanical movement.

The main manufacturers include: Emerson, Rotork, Fighting for the seek, Siemens, AUMA, Honeywell, Johnson Controls, Schneider, Samson, AZBEL, Danforth, Neles, Neptronic, KMC Controls, Dewey, Kennerite, Shenzhen Wancun Controls, Nippon Gear.

Motorized linear actuators

An electric linear actuator is an electro-mechanical device consisting of a motor, linear guide and drive mechanism used to convert electrical energy into linear displacement by mechanical transmission, electromagnetic or thermal expansion to provide straight line push/pull motion; the actuator is driven by a variety of means including ball screw or leadscrews, belts, or voice coils. Typical applications include opening and closing dampers, locking doors, braking machine movements, etc.

In terms of manufacturers, globally, the core manufacturers of electric linear actuators mainly include major manufacturers including: Newport Company, Zaber, Edmund Optics, Progressive Automations, LINAK, Nook Industries, Thorlabs, First Transmission Technology, Physik Instrumente, Actuonix Motion Devices, Quanzhou Optoelectronics, Parker, Venture Mfg. Co., NSK Americas, ABB, Emerson Electric, SKF, Honeywell, THK, IAI, Chiaphua Components, Moteck Electric, Auma, etc.

Rotary Controller

Rotary controllers, also known as servo swing cylinders, servo motors and so on. In summary, the rotary actuator has three major advantages over the linear cylinder: (1) compact structure, which is conducive to the realization of the leg structure of the tubeless, integrated design; (2) can output a stable torque independent of the joint position; (3) suitable for front and rear motion direction symmetrical swing, such as hip, side swing joint swing.

Major manufacturers include: Cowan Dynamics, FESTO, Rotork, Honeywell, Hanbay, VALPES, Compact Automation, Dynamic Corporation Limited, Anderson Eurotech, Emerson, SAMSON, OMEGA, Bürkert, HKS, REXA, Tosoh Technology

| transmission method |

|---|

specification

Basic parameters

| sports event | parameters | unit (of measure) | note |

| Detection method | Geomagnetic + Microwave | ||

| Power supply method | 3.6 | V | lithium-ion battery |

| Average standby current | <10 | µA | |

| operating temperature | -20~65 | ℃ | |

| Storage temperature | -40~85 | ℃ | |

| Detection height | 5~80 | cm | |

| Detection accuracy | >99 | % | |

| communication method | NB-IOT | ||

| connection with high-ranking officials | built-in antenna | ||

| protection class | IP68 | ||

| Product Size | 102*97 | mm |

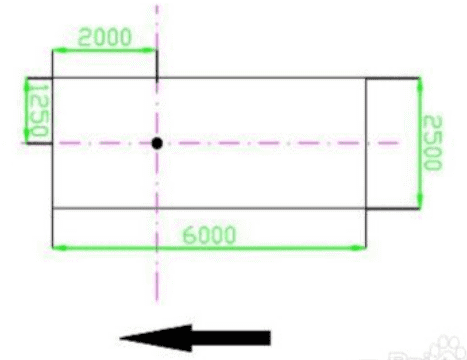

Related drawings

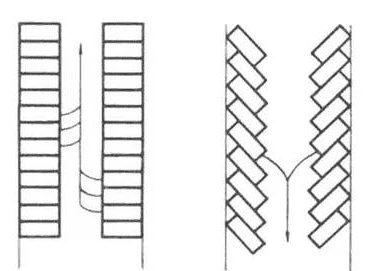

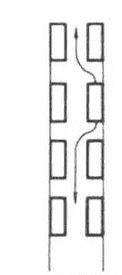

Selection of geomagnetic installation location

1. Type of parking space

Vertical Parking Spaces (Non-Zigzag)

parallel parking

2, a word parking space (side parking) geomagnetic installation parking space geometric center to the curb offset 10cm position;

3、Non-character parking space (parallel parking) geomagnetic installation location to choose the direction of the head of the parking car 1/3;

Installation

1, depending on the actual situation on the site, in the parking space to select the location of the drilling, drilling a depth of slightly more than 105mm, the diameter of 100mm round hole (the effect is shown in the figure below).

2. The geomagnetic equipment needs to be flush with the ground, and the holes are too deep and need to be filled with filler. Fillers can use cement mortar, quick-drying cement, epoxy resin and so on.

3. When installing, the equipment marking and the wide direction of the parking space are in the same direction.

4. Use cement mortar, quick-drying cement, epoxy resin, etc. to fill the gap and clean the top surface of the equipment, which shall be free of slurry and water.

caveat

- After receiving the product, please check whether the package is intact, and check whether the equipment model and specifications are consistent with the product you purchased.

- If replacing the battery, please check the specification model of the battery first, it is strictly prohibited to replace other models of batteries.

- When installing the parking space detector, it is important that there are no stones or sharp objects at the bottom of the holes to prevent the detector from toppling through.

- If there is a ferromagnetic object (e.g. manhole cover) at the installation location (in the middle of the parking space), re-select the installation location. The geomagnetic mounting position should be selected in the parking space 1m away from the edge of the manhole cover.

- The detector is placed into the hole with the front side (the side with the IMEI logo) facing up.

- It is recommended that the front of the detector be level with the pavement and not cover the front of the detector with filler. Then fill in the gaps with filler and clean the pavement when finished. If conditions permit, allow the mix to set before allowing vehicles to park normally.