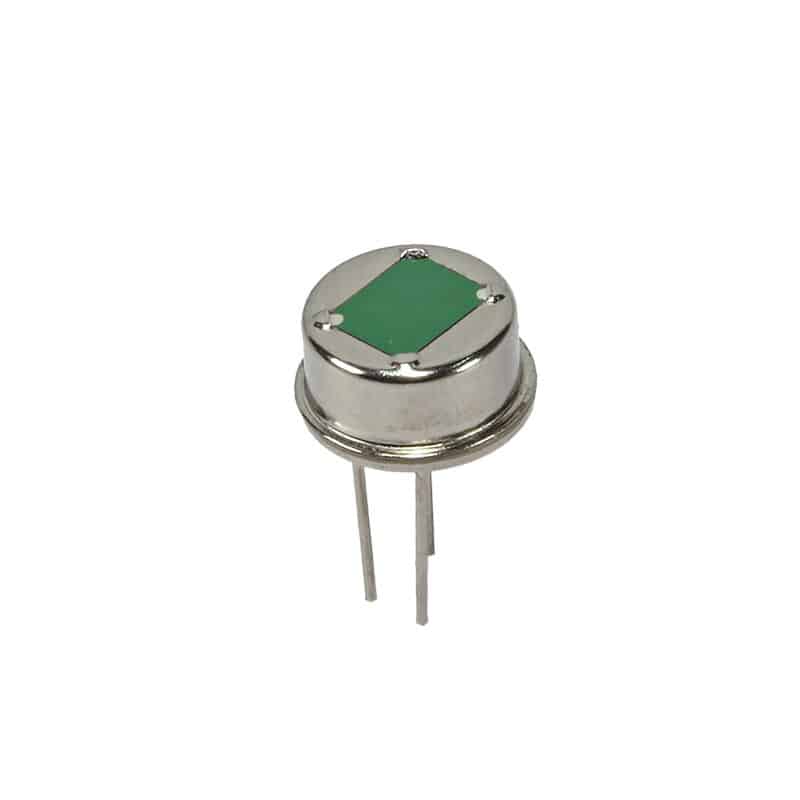

PIR Lead Free Analog Flame Sensor WE-B8F13V43-T39

Product Features

Supports 3.9µm/4.3µm/5.4µm tri-band detection

¥79

Product Overview

Lithium tantalate (LiTaO 3 ) pyroelectric infrared detector is a thermal detector with excellent performance. The Curie temperature of LiTaO 3 crystal material is in the range of 0.5 to 0.5 μm.

Above 600°C, the relative dielectric constant is small, so in a wide range of room temperature, the pyroelectric coefficient of the material varies very little with temperature, and the output

The temperature change rate of the signal is only 1-2 ‰, the temperature stability of the detector performance is very good, and in the wavelength range of 1 ~ 20µm light

The spectral response consistency is very good. Lithium tantalate pyroelectric detectors are mainly used for infrared radiation temperature measurements, spectral measurements, analysis of liquid impurity content.

Gas analysis, radiant power and energy measurement, laser power and energy measurement, open flame detection, human movement alarms, etc...

Product Use

Open fire sensing, detection and early warning; various types of fire alarms, industrial plants / mining / home fire warning alarms, etc.

Instructions for use of the product

(1) Pyroelectric infrared detectors are typical AC devices. When the target is stationary and the temperature is constant, there is no signal output from the pyroelectric infrared detector.

Signal output only occurs when a transient target movement occurs, or a temperature change occurs, or when modulation is performed with a chopper.

(2) In the operation, use and storage of pyroelectric infrared detectors, to avoid rapid temperature changes, when the rate of temperature change is less than 1 ℃ / min.

The detector will not function properly. If the detector heats up too quickly, damage to the lithium tantalate sheet may occur.

(3) pyroelectric infrared detectors have piezoelectricity, sound, electromagnetic waves, vibration are very sensitive, the use of pyroelectric infrared detectors, appropriate reduction of

Shock and shielding are necessary.

(4) When soldering pyroelectric infrared detectors, it is recommended to solder at a position of more than 4 mm, the soldering time should be as short as possible, and use tweezers to hold the root of the tube to help.

Dissipate heat to prevent damage to the detector's sensitive element. Protect the element from dropping. Spare elements should be kept dry.

(5) When the pyroelectric infrared detector is operated, the temperature of the pyroelectric infrared detector is changed due to the contact of the hand, especially after soldering, so that the detector will not be able to operate.

When the detector is working again, wait for a period of time for the detector temperature to equilibrate before resuming normal operation. Immediately after the detector is warmed up, turn on the

power supply, at which point the detector may be in a cutoff state.

(6) Can not use hands and hard objects to touch the window directly, to keep the window clean, when there is dirt, alcohol cotton balls can be used to gently wipe clean.

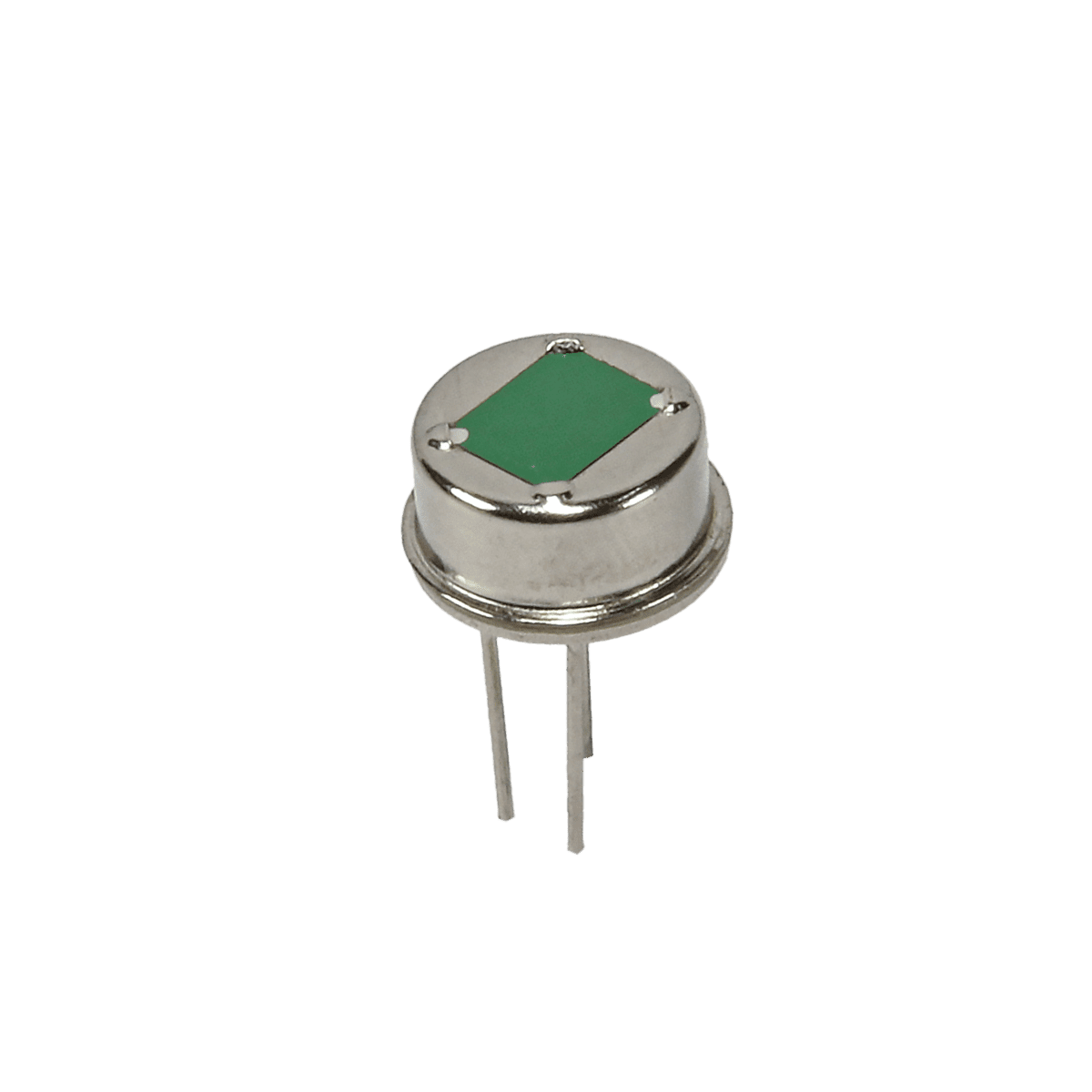

Related drawings

The internal circuit of the detector: pin 1 Vd is the drain of the field effect transistor, plus supply voltage; pin 2 Vs is the output signal pin; pin 3 GND is connected to ground. The lithium tantalate sheet and

A high resistor Rg forms a parallel circuit and is connected to the gate of the field effect transistor. The source output (pin 2) of the external circuit is connected to the ground (pin 3) with 47K.

Ω resistance Rs.