Problems with traditional instrumentation

❶ Functional limitations

- Single measurement function

- Many traditional instruments and meters can usually only accomplish the measurement of one or more specific physical quantities. For example, a traditional flow meter can only measure flow rate and a level meter can only measure liquid level. If you need to obtain data from multiple physical quantities at the same time, you need to use multiple instruments, which not only increases the cost of the equipment, but also complicates the operation.

- Weak data-processing capacity

- Most of the traditional instruments and meters can only simply display and record the measurement data, and lack the function of complex analysis and processing of data. They cannot automatically perform data fitting, statistical analysis, signal processing and other operations.

❷ Accuracy and reliability aspects

- Limited precision

- The accuracy improvement of traditional instrumentation is often limited by the performance of mechanical structures and electronic components. With the increase of use time, the wear and tear of mechanical parts, the aging of electronic components and other factors will lead to a decline in accuracy.

- present bias is susceptible to interference

- Conventional instruments are susceptible to interference in complex electromagnetic environments or harsh physical environments. They are less resistant to electromagnetic interference, and measurement data may travel in industrial environments where strong electromagnetic radiation exists or near large electrical equipment.

❸ Operation and maintenance aspects

- complicated operation

- Traditional instrumentation usually has more knobs, switches and dials, making operation more complicated.

- High maintenance costs

- The maintenance of traditional instrumentation requires specialized technicians, and its internal mechanical and electronic components are more complex. Once a failure occurs, it is more difficult to repair and the replacement cost of parts is also higher.

❹ Poor communication and data transfer capabilities

- Inconvenient data transfer

- Most of the traditional instrumentation lacks modern data communication interfaces, and data transmission mainly relies on manual recording and then input to computers and other devices.

- Remote monitoring is not possible

- Without built-in network communication capabilities, it is difficult for traditional instrumentation to realize remote monitoring and control.

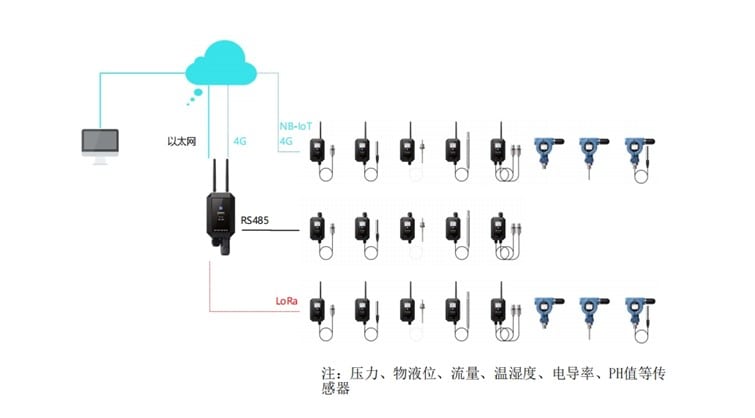

Advantages of Secundum Sensors over Conventional Sensors

- Convenient installationSecurity::

- Wireless sensors do not require wiring, the installation is simply placed in the appropriate location and a simple configuration can be, saving a lot of wiring required time, manpower and material resources, especially for difficult to wire, easy to produce risky areas, such as chemical plants, coal processing and other places.

- For some temporary monitoring projects or application scenarios that require frequent movement of sensor locations, wireless sensors are more flexible to install and can be quickly deployed and adjusted.

- Effectively eliminates the risk of accidents in flammable and explosive locations due to sparks from broken cables.

- High flexibility::

- Wireless sensors can be moved and reconfigured at will, independent of cables, and can be easily adapted to different monitoring needs and environmental changes. For example, in a pharmaceutical plant, wireless sensors can be moved at any time to obtain level data from different areas, depending on the distribution of drugs inside the tank.

- Easy to expand, just add new wireless sensors to the wireless network, you can easily increase the monitoring points and monitoring range, without the need for large-scale modification of the wiring system.

- Low maintenance costs::

- As wireless sensors reduce the use of cables, they reduce the probability of failure due to problems such as cable aging and damage, and reduce the need for regular inspection and maintenance of cables, thus reducing maintenance costs.

- Some wireless sensors support remote configuration and monitoring, technicians can remotely through the network to the sensor parameter adjustment, firmware upgrades and other operations, without having to arrive at the scene, further saving the maintenance time and cost.

- Cost-effective::

- In some large-scale monitoring projects, the individual cost of WorldTech wireless sensors is lower than that of wired sensors, and also eliminates significant wiring costs. Especially for scenarios where a large number of sensors need to be deployed over a wide area, the cost advantage of wireless sensors is even more obvious.

- Wireless sensors can transmit data directly to the cloud or data center through wireless communication technology, which reduces the investment in data acquisition and transmission equipment and lowers system construction costs.

- Adaptation to special environments::

- Wireless sensors are not bound by cables, for some application scenarios that need to work in harsh environments (such as high temperature, humidity, corrosion, vibration, etc.), with better adaptability. For example, in the production workshop of some chemical enterprises, mines and other environments, wireless sensors can avoid cable corrosion and damage, improve the stability and reliability of the system.

- It can be used in some hazardous areas or remote monitoring scenarios that are difficult for personnel to reach, such as combustible gas tanks, sulfuric acid tanks, ship compartments, etc., to realize the remote acquisition of data through wireless transmission to ensure personnel safety.

With Industry 4.0 The further development of the traditional instrumentation of intelligence, miniaturization, integration, networking will be an irreversible trend, our company is committed to research and development of intelligent online sensors14Years of pursuing excellence and innovation, injecting more vitality and momentum into the entire industryThe company has been playing an extremely important role in a wide range of industries.

Application Industries

- Water treatment industry

- Semiconductor industry

- Chemical industry

- Food industry

- Beverage industry

- Feed Industry

- Plastic Industry

- Pharmaceutical industry

- Shipbuilding industry

- Textile industry, etc.

About Us

Hainan Shidian Technology Co., Ltd. to "make the standardization of industrial Internet of Things easier" as the vision, focusing on the direction of the Internet of Things industry chain, indoor positioning, sensing and control and data transmission products in the field of continuous research and development, Lego (Lego) production, precise to meet the small amount of industrial Internet of Things products and a variety of demand characteristics, to provide customer Complex environment and personalized needs to meet the real low inventory, high satisfaction of the new supply and demand relationship.

The company has four R&D centers in Shanghai, Suzhou, Chengdu and Taipei, adhering to the group's nearly 40 years of good business resources and reputation, firmly believe in the "be an expert in the industry" business philosophy, precise in the channel, sensitive to the market, focus on products, "research" is reliable, "production" is stable, "sales" is quality, always focusing on the industrial Internet of Things customers personalized scenarios to meet the ultimate needs. We believe in the business philosophy of "being an expert in the industry", we are precise in channels, sensitive to the market, and focus on products, "research" is reliable, "production" is stable, "sales" is quality, and we are always focusing on the ultimate satisfaction of personalized scenarios of industrial IoT customers.

In terms of products, we have both Zigbee positioning products, which have been cultivated by our self-research team for more than 10 years, and UWB positioning products, which are developed by our teams in Shanghai and Taipei, to meet the different needs of customers for positioning accuracy. At the same time, the company also introduces Bluetooth positioning products to supplement the self-developed solutions, in order to fully meet the needs of all kinds of customers.

Software support we integrate the overall program of various industries, actively open interfaces and source codes for system integrators to join, for related system software companies to do case demonstration based on our products to provide convenience, so that the Internet of Things indoor positioning applications broader.

Content Reviewer:Jimme Yao