Application Background

Auto 4S store maintenance process is complicated, slow to find the car? Car owners can't know the progress of their cars in time, poor experience? With the continuous development of location-based Internet of Things (IoT) information, World Power Technology, through its self-developed ZigBee dual-frequency positioning technology from the production line to the terminal stores, automotive 4S stores have begun to deploy ZigBee dual-frequency positioning system for the maintenance of automobile management, accurate perception of the customer's vehicle location information, and the progress of the work process is clear at a glance.

Application Overview

Multi-process operation time management tracking system

Auto 4S in the traditional maintenance service, many management defects to the customer brings a very bad service experience, the world electricity technology based on ZigBee dual-frequency tag positioning technology, to create a multi-process operation time management tracking system. Through a series of sub-application systems, such as operation big screen signage system, electronic tag activator naming tracking and reporting system, service process logical positioning management, etc., it integrates the process location, service process and location Internet of things technology, so as to make the multi-process time management system realize automation, digitization and visualization, and effectively realize the quantitative management of human effect attendance in multi-process scenarios of automobile 4S stores.

industry pain point

- Inefficient process operations

- Difficulty in managing personnel

- Customer service progress is unavailable

- Difficulty in quantifying human resources attendance

World Power Dual Band Activation Tag and Activator ⬇️

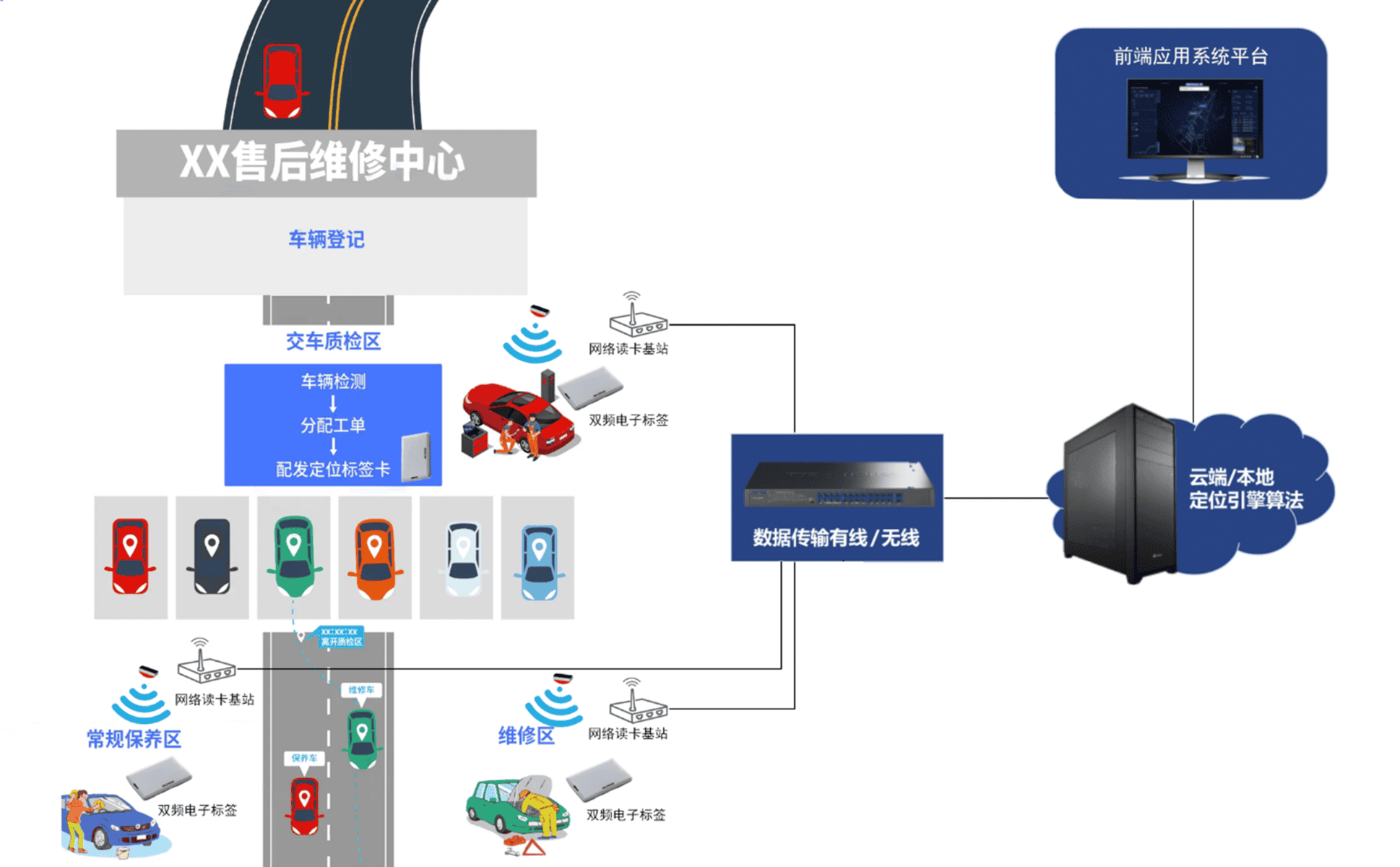

Program Architecture

Vehicle registration quality control:After the maintenance vehicles are registered with license plates and personnel, the vehicles are tested and assigned, and dual-frequency positioning tag cards are issued to bind the license plates.

Vehicle Service Program Zoning:Through the quality inspection after the vehicle service program for partition management, can be divided into routine maintenance area and repair area. Customers can always see the vehicle service progress and vehicle location information from the control center screen; playback view of the vehicle's service progress.

Vehicle delivery:After the vehicle completes the service process, the customer can inquire about the service nodes and details with the dual-frequency positioning tag, and at the same time, account for the labor efficiency, so as to understand the process and the progress of maintenance in real time, and enhance the user experience.

application function

- Precise process label naming management

- Dynamic tracking of electronic tags of served objects

- Automatic matching of work processes for reporting

- Work hour statistics and manpower efficiency analysis for each process

Value Advantage

- Improve the efficiency of process management statistics

- Improved perception of customer service effectiveness

- Automate and visualize personnel attendance

- Optimization and integration of process time and manpower efficiency

Content Reviewer:Jimme Yao