-

×

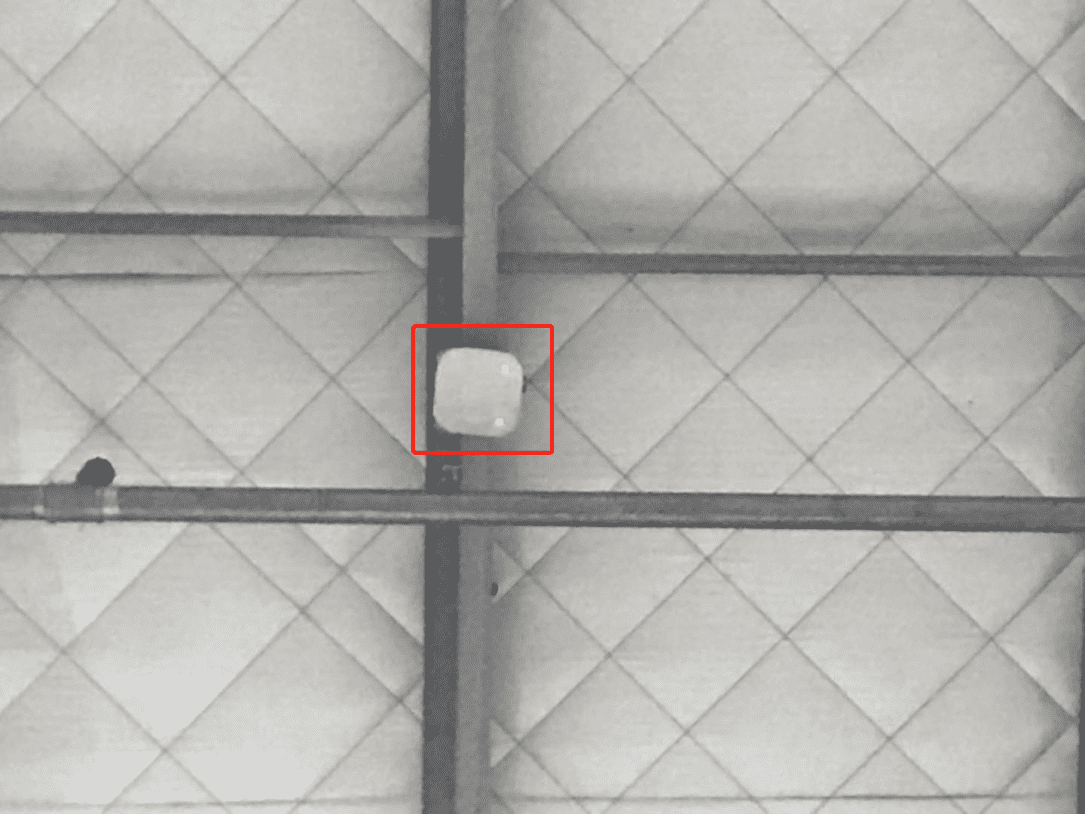

无线网络基站 WE-RWN300 (test)

1 × ¥980

无线网络基站 WE-RWN300 (test)

1 × ¥980

I. Industry status and needs

Logistics is the dynamic state of commodities and other material materials in space and time change. Therefore, to a large extent, logistics management is the management of spatial information and attribute information of commodities and materials. In the intelligent logistics technology process based on the Internet of Things, intelligent terminals use RFID technology, infrared sensing, laser scanning, UWB precise positioning and other sensing technologies to obtain a variety of attribute information of commodities, and then pass to the intelligent data center through communication means to centralize data statistics, analysis, management, sharing, and utilization, so as to provide decision-making support for logistics management and even for the overall business operation. The following pain points exist in the smart logistics industry. The following pain points and needs exist in the intelligent logistics industry:

Pain point 1: In recent years, with the rapid development of e-commerce and manufacturing and other industries, the number of goods in the enterprise warehouse has doubled, in order to improve the utilization rate of warehousing, resulting in more and more dense channel lines in the warehouse, while more and more demand for sorting personnel within the warehouse, the management of the personnel in the warehouse is very challenging.

Pain point 2: Logistics warehouse management is chaotic, the management system is not standardized. Logistics warehouse structure is single, the layout is not reasonable. Some sorting area mixed with the storage area, picking goods randomly stacked in the sorting area of the warehouse, often lose goods, find goods phenomenon.

Pain point 3: enterprise warehouse materials, products, etc. Marking is not clear, or even no marking, there is no reasonable division of the region, but also did not set up the picking path, picking batch, for material management, equipment management, job responsibility management, system management is not strictly formulated, resulting in the issuance of difficult, inaccurate quantity, inventory difficulties and other issues.

Hainan Shidian for intelligent logistics application difficulties and pain points launched a UWB-based wireless positioning technology will be based on the label with the warehouse personnel binding, through the location of personnel information, you can be on the warehouse personnel attendance, leave the post alarm, personnel scheduling management, while the detailed division of each warehouse position, the label with the PDA binding, indirectly locate the position of the goods, for the warehouse access, cargo sorting, inventory, etc. to provide a powerful Data support.

II. Overall programmatic structure

The system includes UWB tag, UWB indoor base station, positioning engine software (C/S architecture) and positioning application system. Positioning tags and positioning base station communicate through UWB pulse signals. The positioning base station transmits the received data from positioning tags to LS1000 positioning engine through 5G network and wired Ethernet for data analysis and processing, and transmits the processed accurate position to the upper layer application through an open API interface.

The system components are as follows:

- UWB tags: card-type and wristband-type, fixed on top of the person or object to be located, can periodically transmit UWB signals with tag ID information.

- UWB Indoor Base Station: communicates with the positioning tags and transmits information back to the positioning engine algorithm software;

- Positioning engine algorithm software: locally deployed, the underlying information data is collected and processed through the algorithm of the positioning engine to get the accurate coordinates of the positioning tag.

- Positioning application software: locally deployed or cloud deployed, the application layer software realizes the basic functions such as positioning display, track playback and other functions, as well as the business functions such as electronic fence, intelligent inspection, attendance statistics and video linkage based on the expansion of location data.

III. Programmatic functions

|

function point |

Functional Description |

|

Personnel tag management |

Distribute tags in accordance with real-name binding, one person, one tag. Before issuing the tags, it is necessary to bind the tags with the designated operators on the platform and enter the personnel information, etc. |

|

Tag management |

The label is bound to the PDA, one PDA and one label. Before issuing the tag, you need to bind the tag with the designated PDA on the platform, enter the PDA code information, etc.

|

|

|

Real-time accurate positioning in the warehouse area, the accuracy of personnel positioning is controlled within 1m, and the walking track in the personnel shelves is in the shelf aisle.

|

|

|

Manage the entry and exit of warehouse personnel, require personnel to enter and exit in accordance with the prescribed entrances and exits, and facilitate the inspection of items carried by personnel entering and leaving the warehouse.

|

|

|

Personnel track playback, you can know the warehouse personnel at a certain time period picking track.

|

|

|

Taking attendance of personnel in the warehouse, counting commute times, mobilization tasks and counting picking goods walking time.

|

|

|

Departure statistics are kept for those who leave the defined work area. |

|

Real-time location management of goods |

Through direct or indirect (such as positioning PDA, pallet, shelf) positioning methods, thus positioning the real-time position of the goods positioning accuracy of about 30cm.

|

|

|

According to the trajectory of goods in and out of the warehouse, optimize the layout of the division of the warehouse to enhance the efficiency of goods operation. |

|

|

Get the associated positioning tag ID according to the PDA ID in the parameter at the time of warehousing, get the nearest positioning coordinates under the scan time in the parameter, calculate which warehouse position it falls in, update the warehouse position of the goods according to the waybill number/running number in the parameter, and send the warehouse position to the backend.

|

IV System-related hardware

V Physical photographs of on-site installation

Editor-in-chief of the website.

Content review.

Content review.