Applications

Smart Factory Energy Consumption Control IoT Solution by World Power Technology Co.

发表于 应用案例 |I. Status quo and demand for energy consumption control in factories

In recent years, with the booming development of China's industrial industry, factories have become the whole society's energy consumption and emission of large households, the construction of economizing

The call of factories is becoming stronger and stronger. At present, most factories and workshops in China basically rely on manual meter reading to count electricity consumption and energy consumption.

The status of source consumption and the current status of plant control is as follows:

- Factory geographical distribution, the number of various types of equipment, usually by the master workers through the basic equipment display data and the appearance of the equipment for equipment inspection, equipment management is relatively rough, the internal operating status of the equipment and some of the problems affecting the normal operation of the equipment can not be understood in a timely manner;

- There are many energy consumption measurement points, many types of energy media, and the measurement points are scattered in various workshops, so it has long been relying on manual meter reading and statistics, which is a waste of manpower and not very efficient;

- The energy metering information obtained manually is small, the processing cycle is long, and some hidden problems, such as large energy consumption waste, cannot be detected in time and reasonable measures can be taken.

Using IoT communication technology, it is possible to monitor the dynamic information of energy consumption of the whole factory online and to connect these energy consumption data with the corresponding

With the combination of equipment data, on-site operation management personnel can understand and master the real-time energy consumption status of key equipment and the number of unit energy consumption.

Information such as data, energy consumption trends and real-time operating parameters.

Based on the core IoT gateway technology and communication technology, World Power Technology has launched the smart factory energy control IoT hardware solution.

Programs.

Second, intelligent factory energy consumption control Internet of Things solutions

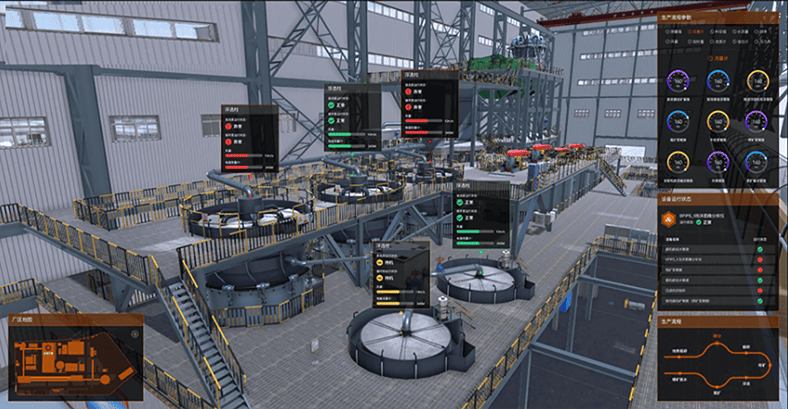

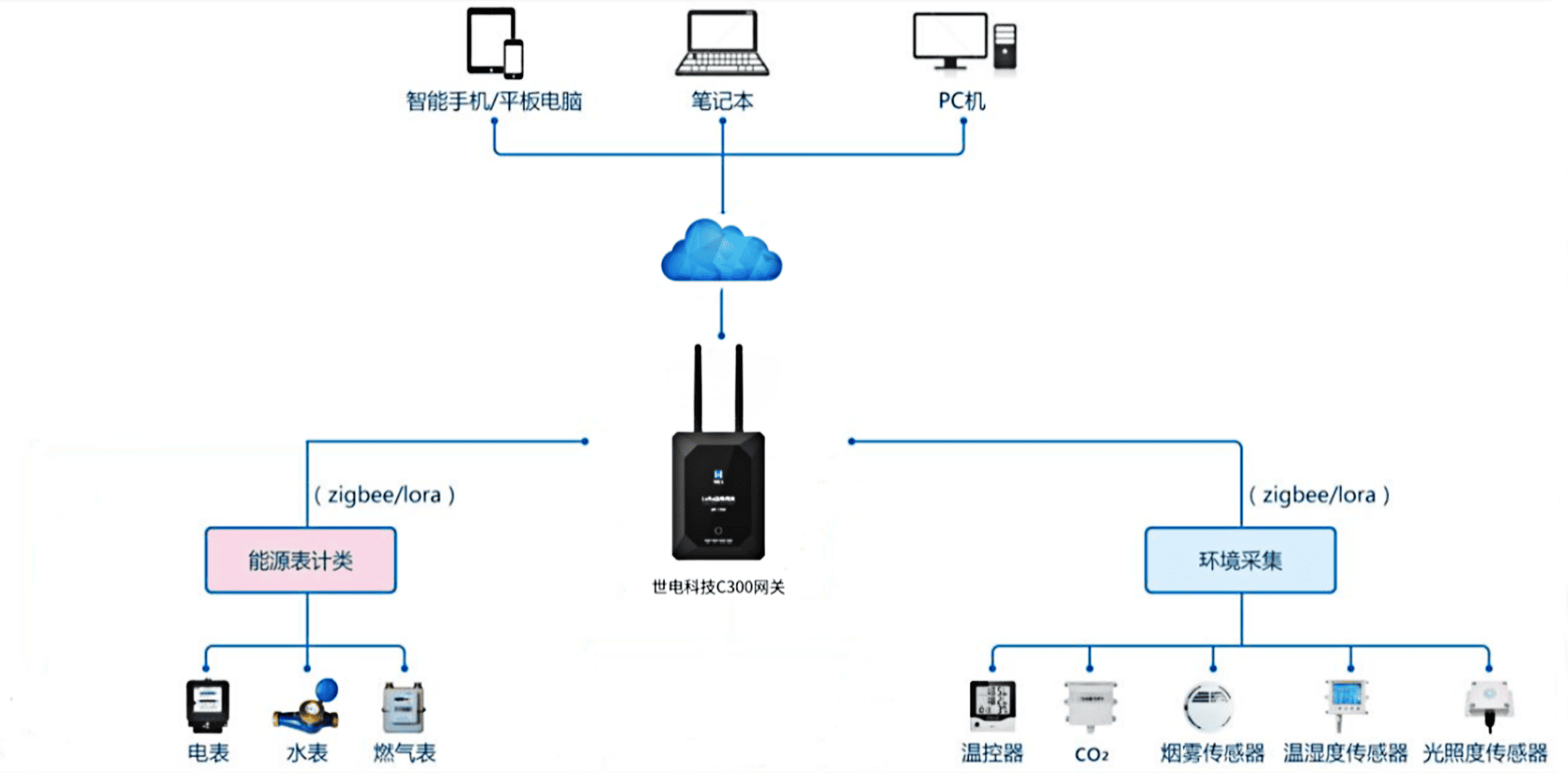

Based on C300 gateway, World Power's intelligent factory energy consumption control solution realizes intelligent control of factory electrical equipment and water, electricity, gas, etc. through downstream energy consumption, environment sensors and terminal control devices, and avoids waste of energy consumption through control strategy optimization.

Main objectives of the program

- Coverage of the entire plant, plant area IOT communication gateway, upstream support 4G/NET, downstream support ZigBee/LoRa/RS485, basically can be connected to a variety of wireless technology and wired technology terminals;

- Realize online monitoring, automatic collection and storage of all kinds of energy consumption data and energy efficiency indexes, and provide flexible and diversified query methods. ZigBee/LoRa/RS485 wireless and wired mixed networking can be provided for water, electricity and gas; if there are existing devices on site, they can be uploaded by wireless or wired 485 serial port connection;

- A variety of environmental acquisition sensors are available for each plant environment, including temperature and humidity, light, CO2 concentration, and other environmental data;

- Can also be required to realize the switch inside the plant, the collection of special equipment, providing wireless serial port and switching control equipment, to achieve remote switching control

III. Introduction to Hainan Shidian

Hainan Shidian Technology Co., Ltd. to "make the standardization of industrial Internet of Things easier" as the vision, focusing on the direction of the Internet of Things industry chain, indoor positioning, sensing and control and data transmission products in the field of continuous research and development, Lego (Lego) production, precise to meet the small amount of industrial Internet of Things products and a variety of demand characteristics, to provide customer Complex environment and personalized needs to meet the real low inventory, high satisfaction of the new supply and demand relationship.

The company has four R&D centers in Shanghai, Suzhou, Chengdu and Taipei, adhering to the group's nearly 40 years of good business resources and reputation, firmly believe in the "be an expert in the industry" business philosophy, precise in the channel, sensitive to the market, focus on products, "research" is reliable, "production" is stable, "sales" is quality, always focusing on the industrial Internet of Things customers personalized scenarios to meet the ultimate needs. We believe in the business philosophy of "being an expert in the industry", we are precise in channels, sensitive to the market, and focus on products, "research" is reliable, "production" is stable, "sales" is quality, and we are always focusing on the ultimate satisfaction of personalized scenarios of industrial IoT customers.

In terms of products, we have both Zigbee positioning products, which have been cultivated by our self-research team for more than 10 years, and UWB positioning products, which are developed by our teams in Shanghai and Taipei, to meet the different needs of customers for positioning accuracy. At the same time, the company also introduces Bluetooth positioning products to supplement the self-developed solutions, in order to fully meet the needs of all kinds of customers.

Software support we integrate the overall program of various industries, actively open interfaces and source codes for system integrators to join, for related system software companies to do case demonstration based on our products to provide convenience, so that the Internet of Things indoor positioning applications broader.

Content Reviewer:Jimme Yao