summarize

In the IoT field, we often use liquid level sensors when we want to measure the position and state of a particular liquid (water or oil). Liquid level sensors, also known as level switches, are designed to change state when immersed in a liquid, and they are used to determine if a specific level of liquid or oil is present in a container.

Liquid level sensors are one of the very important sensors that play a very important role in various consumer/industrial applications. Industrial applications include level sensing in transportation tanks, storage tanks and water treatment tanks, as well as liquids used in the petrochemical industry to detect liquids such as gasoline, diesel and other fuels. Liquid level measurement is very important in household applications including electronic devices such as water dispensers, water evaporators, steam cookers, boiler monitoring systems, heating systems, washing machines, steam irons, juicers, automatic coffee makers, and more. WithOther types of sensorsLikewise, level sensors can be used or can be designed using a variety of sensing principles

Level sensors can be broadly categorized into three types based on the number of locations where the fluid (or fluid solids) is to be sensed:

Sensor Classification

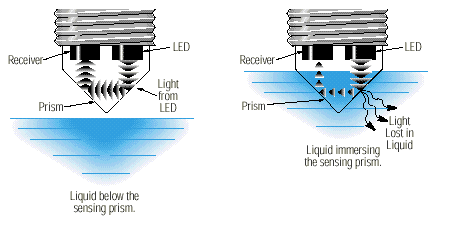

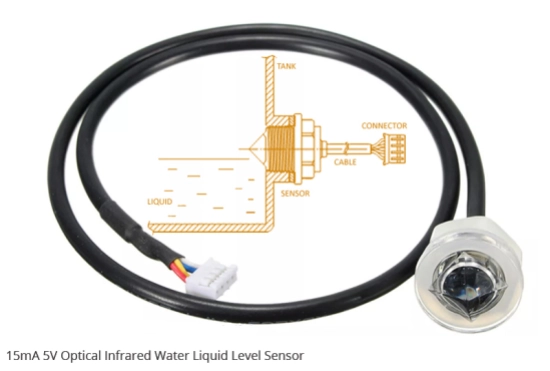

Optical Level Sensors

The sensor contains an infrared light emitting diode and a phototransistor. Since the light from the light emitting diode is transmitted to the sensor's optical head, the phototransistor receives zero light (or less) when the sensor is immersed in a liquid, since the transmitted beam will be refracted. If there is no liquid, the transmitted light will be reflected directly back to the phototransistor through the optical head. Therefore, if the sensor detects a liquid level, it will output a "low level" signal!

These sensors can detect the presence or absence of almost any liquid. They are insensitive to ambient light, unaffected by bubbles in air and small air bubbles in liquids. This makes them useful where changes in status must be recorded quickly and reliably, and they can operate reliably for long periods of time without maintenance.

The disadvantage of an optical level sensor is that it can only determine the presence or absence of liquid.

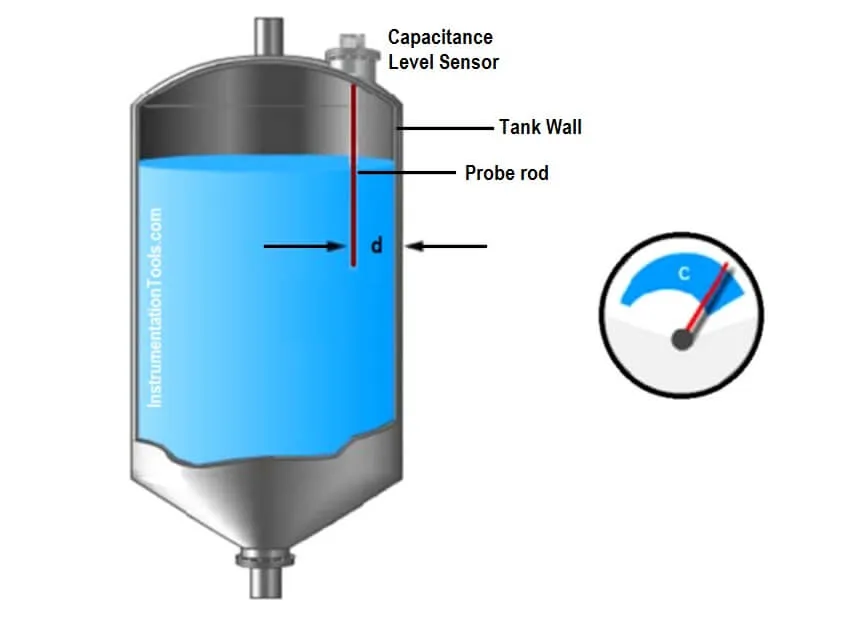

Capacitive Level Sensors

The principle of capacitive level measurement is based on changes in capacitance. Capacitive sensors have two plates: one plate is used as an insulating electrode and the other plate is used as the tank wall. The capacitance depends on the liquid level. Empty tanks have a low capacitance, while filled tanks have a higher capacitance. A simple capacitor consists of two electrode plates separated by a small thickness of insulator (e.g. solid, fluid, gas or vacuum).

The advantage of a capacitive level switch is that it can be used to determine the rise or fall of liquid in a vessel. By making the electrodes the same height as the vessel, the capacitance between the electrodes can be measured. No capacitance means no liquid. Full capacitance means full vessel. "Empty" and "full" measurements must be recorded, and then the level must be displayed using a meter calibrated to 0% and 100%.

C = E (KA/d) where: C = capacitance in picoseconds farad (pF) E = a constant known as the absolute permittivity of free space K = the relative permittivity of the insulating material A = the effective area of the conductor d = the distance between the conductors. One of their disadvantages is that electrode corrosion can change the capacitance of the electrodes, requiring cleaning or recalibration. They are also more sensitive to the type of fluid used.

Conductive Level Sensors

Conductive level switches are sensors with electrical contacts at a specific liquid level. Two or more insulated electrodes with exposed tips are used to lower into the liquid in a pipe. The longer electrodes carry a low voltage, while the shorter electrodes are used to complete the circuit when the liquid level rises to meet it. When the liquid covers the probe, its electrodes form a portion of the circuit, causing current to flow and a high or low level signal to be emitted.

Like capacitive level switches, conductive level switches depend on the conductivity of the liquid. Therefore, they are only used to measure certain types of liquids. In addition, the tips of these sensors must be cleaned regularly to minimize scaling

Diaphragm Level Sensor

Diaphragm or pneumatic level switches rely on air pressure to push a diaphragm, which engages a microswitch inside the body of the device. As the level increases, the internal pressure in the detection tube will increase until the microswitch is activated. As the level drops, the air pressure will also drop and the switch opens.

The advantages of a diaphragm-based level switch are that there is no need for a power source in the tank, it can be used with many types of liquids, and because the switch is not in contact with the liquid. However, since it is a mechanical device, it will require maintenance over time

Float Level Sensor

Float switches were the original level sensors. They are mechanical devices. A hollow float is attached to an arm. The arm is pushed up and down as the float rises and falls in the liquid. The arm can be connected to a magnetic or mechanical switch to determine on/off, or it can be connected to a gauge that goes from full to empty as the level drops.

Float switches in toilet tanks are the most commonly used float level sensors. Sump pumps also use float switches as a cost-effective way to measure water levels in basement sumps. Since they are mechanical, they must be used more frequently than other level switches

Float switches can measure any type of liquid and can be designed to operate without any power supply.

Ultrasonic Level Sensor

Ultrasonic water level sensors work on the principle of ultrasonic transducer (probe) when encountering the measured level (object) surface emits a high-frequency pulsed sound wave, which is reflected, and the reflected return wave is received by the sensor. Transducer and converted into an electrical signal. The propagation time of the sound wave. It is proportional to the distance from the sound wave to the surface of the object. The sound wave propagation distance S with the speed of sound C and sound propagation time T can be expressed by the formula: S = C × T / 2.

Because there is no contact with the fluid to be measured, ultrasonic level measurement technology can be used in applications where sensors that require contact are prohibited. These sensors have no moving parts and are therefore very reliable and require little maintenance.

Vibrating fork or tuning fork level sensors

Application level control of liquids, powders and fine grained solids in the mining, chemical processing and food and beverage industries. The operating principle is based on a tuning fork transducer at its intrinsic frequency and detects changes in frequency and amplitude in the presence of the application medium.

Vibration sensor technology is well suited for solids and liquid level control, including viscous materials and foams, as well as powders and fine-grained solids. However, the types of applications where tuning forks can be used are limited to spill or dry run type applications and they do not provide continuous process measurement. They can, however, be used in conjunction with a continuous level detection system as an alarm point for overfills and spills.

Radar Level Sensor

A radar level meter is a level measuring instrument based on the time travel principle. Radar waves travel at the speed of light and the travel time can be converted into a level signal by electronic components. The detector emits high frequency pulses that travel at the speed of light in space. When the pulses encounter the surface of the material, they are reflected and received by a receiver inside the instrument, which converts the distance signal into a level signal.

The radar sensor uses a special time interval adjustment technique to amplify and localize the echo signals per second and then analyze and process them. Therefore, the radar sensor can accurately and carefully analyze and process these amplified echo signals within 0.1s without spending a lot of time analyzing the frequencies.

Selection of level sensors

Users can choose according to the medium to be measured, cost, accuracy and installation.

| typology | medium | dominance | inferior |

| float | fluids | Accurate measurement Unaffected by foam and viscosity Inexpensive and maintenance-free | Low wave-sensitive measuring range (< 1 m) Not suitable for corrosive products |

| hydrostatic | fluids | Accurate measurement independent of foam and viscosity, easy to install Wide measurement range | Requires regular maintenance Diversion required for intervention |

| radar (loanword) | Liquid Solid Paste | Non-contact measurements maintenance-free, easy to install very precise measurements Adjustable measuring range withstands high temperatures (up to 450°C) | Sensitivity to conductive products |

| control (the course of sth) | Liquid Solid Paste | Non-contact measurement very precise measurement Unaffected by product surface disturbances Extremely low sensitivity to the environment Wide measuring range | Sensitivity to conductive products |

| ultrasound (scan) | Liquid Solid | Non-Contact Measurement Accurate Measurement, Self-Cleaning. Maintenance-free, wide measuring range, easy to install | Sensitive to temperature changes, sensitive to temperature extremes Not suitable for foaming and dusting products, sensitive to conductive products |

| capacitive | Liquids Granular products Powder | Easy to install Withstands very high temperatures and pressures Heavy duty Insensitive to sticky and tacky products | |

| radiate | All types of fluids | Suitable for all applications Non-contact measurement Insensitive to product characteristics Resistant to corrosive products Resistant to extreme temperatures and pressures | Expensive technology Requires regular maintenance |

Sensor Manufacturers

- Siemens (company name)

- Gaines (name)

- Honeywell (name)

- Xiamen Zhiheng

- ifm electronic

- Sapcon Instruments

- CAPTRON

- UWT GmbH Level Control

- EUGEN WOERNER GmbH & Co. KG

- Pulsar Measurement

- GEMS SENSORS & CONTROLS

- WIKA Alexander Wiegand SE & Co. KG

- VEGA Grieshaber KG

- Trimod'Besta

Water Level Sensor Application Scenarios

Uses for water level sensors include the following applications:

- Water level measurement in pools and tanks

- Measurement of river and lake levels

- sea level survey

- Acid and alkali liquid level measurement

- Fuel level measurement of fuel trucks and mailboxes

- Swimming pool water level control

- Tsunami early warning and sea level monitoring

- Cooling tower water level control

- Sewage pump level control

- Remote level monitoring

Related resources

Content review.