-

×

无线网络基站 WE-RWN300 (test)

4 × ¥980

无线网络基站 WE-RWN300 (test)

4 × ¥980

Applications

Exploring Intelligent Navigation for Manufacturing Companies - RTLS System Explained

发表于 应用案例 |I. Changes and challenges for manufacturing companies

With the advancement of Industry 4.0, manufacturing companies are facing many challenges. Problems such as rising labor costs, inventory management and worker shortages are becoming more and more prominent. In the process of automation and intelligence, although integrated solutions are widely used, there may be underlying blind spots and shrinking benefits. For example, in the context of Industry 4.0, although integrated design and manufacturing solutions try to break down the walls between enterprises through the Internet and realize the collaborative development of the industrial chain, in practice, they may lead to operational disruptions and high costs due to various factors.

Industry 4.0 is the digital transformation of manufacturing through intelligent means, the core of which lies in the application of technologies such as the Internet of Things, big data, and artificial intelligence to the production process. However, in the process of creating smart factories by many manufacturing enterprises, the intelligent transformation of core production lines and heavy machinery and equipment often lacks systematization and comprehensiveness. On the one hand, enterprises have developed from internal integration to industry chain synergy, such as the adoption of design and manufacturing integration programs involving component design outsourcing, vehicle design outsourcing and other modes, but this has also brought about difficulties in resource integration and management. On the other hand, the traditional mode of production and operation is facing the dilemma of sharp reduction of labor force, increase of labor cost, insufficient production capacity, low efficiency, and processing quality cannot be guaranteed in the face of the economic "new normal". For example, some enterprises are stuck in a labor-intensive state, with high management costs, low productivity, and product quality relying on human technical ability, which is prone to uneven quality.

Under such circumstances, real-time positioning technology has attracted much attention as a cost-effective and less disruptive solution. It can provide manufacturing companies with finer indoor location-type data, accurate to the centimeter level, to track the manufacturing process, production material flow or finished product transfer, and to know in real time the location of all key components at any point in time, which can help companies to solve bottlenecks and improve production efficiency and management.

Overview of the RTLS system

2.1 What is an RTLS system

A Real-Time Location System (RTLS) is a system that utilizes advanced sensor technology and positioning algorithms to monitor and track the location of objects in real time. It consists primarily of tags, readers/receivers, back-end systems, and user interfaces, often referred to as a local positioning system that displays what, where, and when within a defined area, quantifying this data in a way that is understandable to the application.

For example, on a manufacturing floor, RTLS can show which order passed through which production area at a given time, or which transferable box was loaded onto which consolidation truck during working hours.RTLS systems typically include a series of reader antennas and base stations located in wall or ceiling deployments in the monitored area that capture location information from the electronic tags tied to assets or people as they move, and in real time Generates tag location data, as well as historical readings of movement and even the number of passes and length of stay at a finger point.

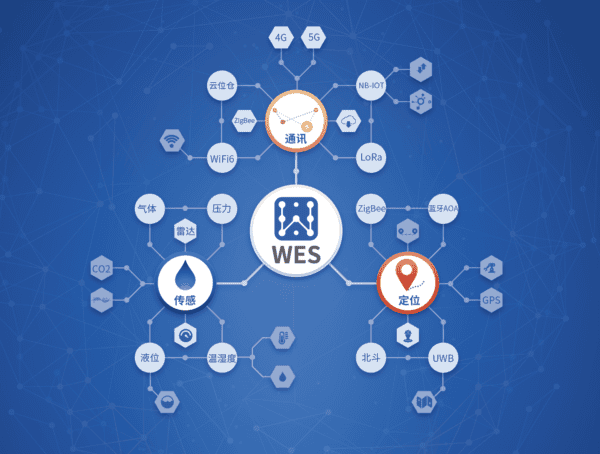

2.2 World Wide Web's ZigBee Indoor Positioning Technology

WorldTech provides powerful indoor positioning solutions for manufacturing companies based on ZigBee technology, a low-power, low-data-rate wireless communication technology featuring large network size, self-organizing networks, low cost, high reliability, and strong security.

WorldTech's ZigBee indoor positioning technology provides manufacturing companies with indoor finding, locating and inventory solutions, as well as various types of acousto-optic electronic tags. With the "Lego" production model, SEEDI is able to meet the different needs of the industrial IoT industry, which is widely used in a variety of fields.

In manufacturing enterprises, SEEDI's ZigBee indoor positioning technology enables more efficient and accurate inventory management, improves production efficiency, optimizes processes, enhances shop floor safety management, and provides enterprises with newer and better business intelligence. For example, by locating work-in-process, finished goods and raw materials in real time, enterprises can accurately grasp the flow of materials, optimize production layout, reduce inventory backlog and improve asset utilization. At the same time, WorldTech's ZigBee indoor positioning technology can also be integrated with other enterprise management systems to realize intelligent production management.

In conclusion, ZigBee indoor positioning technology from SEEDAN provides an efficient, reliable and cost-effective real-time positioning solution for manufacturing enterprises, helping them realize intelligent transformation and enhance competitiveness.

III. Benefits of RTLS

3.1 Efficient inventory management

Efficient inventory management is critical in manufacturing organizations. Real-time locating systems (RTLS) can provide many benefits to organizations by helping them locate missing inventory, reduce search time and unnecessary replacements, increase efficiency and productivity, and reduce operating costs.

First, RTLS provides the ability to automate inventory reporting. Instead of having to plan time to shut down operations and check critical tools, find missing items, or individually rescan materials that never moved, inventory becomes an autonomous, always-up-to-date process. Inventory managers can also create customized alerts when an item leaves its allowed area, is low in quantity, or reaches another performance parameter.

Second, RTLS can reduce paperwork in the checkout process. For environments like factories where thousands of parts move every day, checking tools or rental equipment in and out can be a headache. And by automating these processes with RTLS, such as knowing where workers are and where critical items belong, the checkout process can be reduced to a single step: picking up the items you need.

Further, RTLS provides the ability to quickly locate missing items. Instead of traveling to the plant floor to begin a search when an item is not where it should be, plant workers can simply enter identifying information on a mobile device to view a current picture of where the asset is now. Some wayfinding RTLS solutions even provide a path from the worker's current location to the desired item.

In addition, RTLS can generate usage data. Lost items are unlikely to be used, and items placed in their normal location may sit unused. Real-time location data provides a simple way to study the usage and needs of vehicles, machines, tools and even individual workstations, helping to identify equipment shortages or backlogs in other areas, which translates into higher productivity and increased revenue in areas where more items need to be purchased.

Finally, RTLS enhances other technologies and existing workflows. Rather than eliminating the way manufacturers have already crafted ways of doing things, it can be used to inform, research, evaluate, or update virtually any job that involves a location, from assembly line processes to quality control to loading and delivery.

WorldTech's ZigBee indoor location technology excels in inventory management. By locating raw materials and parts, tooling and inventory in real time, companies can get an accurate picture of material flow, optimize production layouts, reduce inventory backlogs and improve asset utilization.

3.2 Improve manufacturing process efficiency

RTLS also plays an important role in improving the efficiency of manufacturing processes. It includes tracking work-in-progress, locating machines and identifying bottlenecks to optimize the production process.

RTLS is able to collect and communicate time and motion data during the manufacturing process. Companies can obtain data on how objects are actually moving and analyze the patterns behind these moving parts. Real-time position data can show which spaces can be optimized, motion history can reveal anomalies in the normal production process, and timing data can quantify the time required for each production stage.

RTLS can also provide early warning signals, allowing for increased asset visibility and early detection of problems. When the location of a key piece of equipment remains unchanged for an extended period of time, it could mean that the equipment is failing, and the system can provide an early warning in time for maintenance personnel to take care of it, avoiding disruption to the production schedule.

Location data can provide affirmative updates, such as marking an item's progress from assembly to quality control, or triggering status updates when manufactured parts advance from one step to another. Location-based work-in-progress (WIP) tracking can provide a detailed, real-time picture of the progress and sequence of critical processes, helping to reduce the number of manual scans and required processes.

The RTLS system reduces errors by automatically updating in real time, rather than only at scanning time. In a manufacturing process with 30 steps, if each step is documented using manual scanning, missing scanning points can cause problems throughout the process if staff don't catch errors immediately. With the RTLS system, on the other hand, it is possible to map all key location points between each scan, virtually eliminating the scans themselves and making the process more accurate, efficient and agile.

Bottlenecks and obstacles between the start and end of a project can be costly. With the RTLS system, tracking location data at the regional level can show the difference in time required for a particular project at different sites. More accurate location data or tracking history can help pinpoint where and when each delay began so that problem-solving plans are based on real data, not just best guesses.

WorldCom's ZigBee indoor location technology tracks work-in-progress in real-time, helping organizations quickly identify bottlenecks and problems, adjust production schedules in time, and avoid wasting resources. At the same time, it can be integrated with other enterprise management systems for intelligent production management.

3.3 Improvement of workshop safety management

RTLS systems can improve shop floor safety management, safeguard workers, and provide new business intelligence for continuous improvement.

RTLS systems have a variety of applications in worker safety and security. For example, contact tracing can help identify who was in contact with whom at the time of the infection problem. In the current work environment, especially in locations such as factories, human contact is critical to outbreak prevention and control. Many contact tracing solutions are now in use in manufacturing organizations, with the primary goal of quickly identifying who has been in contact with whom in the event of an infection. Using RTLS for contact tracing has clear advantages because real-time location data not only shows the time, place and duration of any person's interactions, but also the amount of time an individual spends in between those interactions.The anti-collision function provides real-time data that, in combination with other safety measures, reduces workplace accidents. Workplace accidents cause huge losses to factories every year, with collisions being one of the main perpetrators. Existing safety measures include bright signage, audible alarms for vehicle or personnel movement, indoor traffic lights, deployable safety buffers, extensive training, and protective gear for individual workers. RTLS, on the other hand, provides real-time data that can better inform the use of other safety measures.

RTLS systems can also prevent collisions by identifying congested or dangerous areas. Real-time location data identifies congested or dangerous areas and provides advance warning to prevent collisions. For example, in employee location tracking, by equipping each employee, contractor or site visitor with a tag, their precise location can be identified in real time. The geo-fencing feature allows any number of virtual zones to be set up to represent geographic boundaries and automatically triggers a response when a tracking tag enters or leaves an area.

WorldTech's ZigBee indoor positioning technology monitors personnel safety in real time, ensuring that employee activity in hazardous areas is restricted. At the same time, the system is able to provide real-time alarms to deal with potential safety hazards in a timely manner, providing a better safety management solution for organizations.

IV. Long-term advantages of the RTLS system

The long-term advantage of the RTLS system is to continuously provide enterprises with accurate location data to support their digital transformation and intelligent development. It is specifically manifested in the following aspects:

4.1 Increased productivity and quality

In manufacturing enterprises, RTLS systems can track every link in the production line in real time, helping managers to quickly identify bottlenecks and problems, adjust production plans in time and avoid wasting resources. For example, with real-time data, companies can know exactly where work-in-progress is located, optimize production layout, and improve production efficiency. At the same time, the RTLS system can also provide early warning signals, enabling increased asset visibility and early detection of problems. When the location of a key piece of equipment remains unchanged for a long period of time, it may mean that the equipment is malfunctioning, and the system can send out an early warning in time so that maintenance personnel can handle the situation and avoid affecting the production schedule.

In addition, the RTLS system can be integrated with other management systems of the enterprise to realize intelligent production management. For example, by analyzing real-time location data, production processes can be optimized, inventory management efficiency can be improved, and worker safety and security can be enhanced. WorldTech's ZigBee indoor positioning technology excels in this area and can provide manufacturing enterprises with efficient, reliable, and low-cost real-time positioning solutions, helping them realize intelligent transformation and enhance competitiveness.

4.2 Optimize inventory management

Efficient inventory management is critical for manufacturing organizations. the RTLS system provides the ability to automate inventory reporting. inventory no longer requires planning time to shut down operations and check critical tools, find missing items, or individually re-scan materials that never move, but becomes an autonomous, always up-to-date process. Inventory managers can also create customized alerts when an item leaves its allowed area, is low in quantity, or reaches another performance parameter.

RTLS systems can also reduce paperwork in the checkout process. For environments like factories where thousands of parts move every day, checking tools or rental equipment in and out can be a headache. And by automating these processes with RTLS, such as knowing where workers are and where critical items belong, the checkout process can be reduced to a single step: picking up what you need.

In addition, RTLS systems can provide the ability to quickly locate missing items. Instead of traveling to the plant floor to begin a search when an item is not where it should be, plant workers can simply enter identifying information on a mobile device to view a current picture of where the asset is now. Some wayfinding RTLS solutions even provide a path from the worker's current location to the desired item.

RTLS systems can also generate usage data. Lost items are unlikely to be used, and items placed in their normal location may sit unused. Real-time location data provides an easy way to study the usage and needs of vehicles, machines, tools and even individual workstations, helping to identify equipment shortages or backlogs in other areas, which translates into higher productivity and increased revenue in areas where more items need to be purchased.

WorldTech's ZigBee indoor location technology excels in inventory management. By locating raw materials and parts, tools and inventory in real time, companies can get an accurate picture of material flow, optimize production layouts, reduce inventory backlogs and improve asset utilization.

4.3 Enhancement of workshop safety management

RTLS systems can improve shop floor safety management, safeguard workers, and provide new business intelligence for continuous improvement. RTLS systems have a variety of applications in worker safety and security. For example, contact tracing can help identify who was in contact with whom at the time of the infection problem. In the current work environment, especially in locations such as factories, human contact is critical to outbreak prevention and control. Many contact tracing solutions are now in use in manufacturing organizations, with the primary goal of quickly identifying who has been in contact with whom in the event of an infection. Using RTLS for contact tracing has clear advantages because real-time location data not only shows the time, place and duration of any person's interactions, but also the amount of time an individual spends in between those interactions.

Collision avoidance provides real-time data that, in conjunction with other safety measures, can reduce workplace accidents. Workplace accidents cost factories a great deal of money each year, with collisions being one of the main perpetrators. Existing safety measures include bright signage, audible alarms for vehicle or personnel movement, indoor traffic lights, deployable safety buffers, extensive training, and protective gear for individual workers. RTLS, on the other hand, provides real-time data that can better inform the use of other safety measures.

RTLS systems can also prevent collisions by identifying congested or dangerous areas. Real-time location data identifies congested or dangerous areas and provides advance warning to prevent collisions. For example, in employee location tracking, by equipping each employee, contractor or site visitor with a tag, their precise location can be identified in real time. The geo-fencing feature allows any number of virtual zones to be set up to represent geographic boundaries and automatically triggers a response when a tracking tag enters or leaves an area.

WorldTech's ZigBee indoor positioning technology monitors personnel safety in real time, ensuring that employee activity in hazardous areas is restricted. At the same time, the system is able to provide real-time alarms to deal with potential safety hazards in a timely manner, providing a better safety management solution for organizations.

4.4 Support for the digital transformation of enterprises

With the advancement of Industry 4.0, the digital transformation of enterprises has become an inevitable trend. RTLS system can provide enterprises with accurate location data to support their digital transformation and intelligent development. For example, through the analysis of real-time location data, production processes can be optimized, inventory management efficiency can be improved, and worker safety and security can be enhanced. Meanwhile, RTLS system can also be integrated with other management systems of enterprises to realize intelligent production management.

WorldTech's ZigBee indoor positioning technology can provide manufacturing companies with indoor finding, locating and inventory solutions, as well as various types of acousto-optic electronic tags. Through the "Lego" production model, SEEDS is able to meet the different needs of the industrial IoT industry, which is widely used in a variety of fields. In manufacturing enterprises, SEEDI's ZigBee indoor positioning technology can achieve more efficient and accurate inventory management, improve production efficiency, optimize processes, enhance shop floor safety management, and provide enterprises with newer and better business intelligence.

In conclusion, the long-term advantage of RTLS system is to continuously provide accurate location data to enterprises, supporting their digital transformation and intelligent development. WorldTech's ZigBee indoor positioning technology provides manufacturing enterprises with an efficient, reliable, and low-cost real-time positioning solution, helping them realize intelligent transformation and enhance competitiveness.

v. evaluation and selection of rtls systems

Choosing the right RTLS system for your organization's specific needs and environment is critical. With its flexibility and affordability, the WES-RTLS system from Seiden Technology is the ideal choice for heavy industrial plants.

5.1 Key Factors in Evaluating RTLS Systems

- positioning accuracy: Different application scenarios have different requirements for positioning accuracy. For example, in some scenarios that require precise tracking of high-value assets, such as the positioning of parts in an automobile manufacturing plant, a high-precision positioning system can ensure that the location of each part is accurately grasped, improving production efficiency and quality control. For scenarios with relatively low accuracy requirements, such as general material management, a slightly lower accuracy positioning system can also meet the demand. WorldTech's ZigBee indoor positioning technology can provide flexible positioning accuracy options according to the needs of different scenarios to meet the diverse needs of enterprises.

- cost-effectiveness: When choosing an RTLS system, an enterprise needs to consider the deployment cost, labeling cost, and long-term operational cost of the system. Some positioning technologies, such as UWB, have high positioning accuracy but also relatively high deployment and tagging costs. In contrast, WorldTech's ZigBee indoor positioning technology provides an affordable solution for organizations with its low cost and cost-effective advantages. WorldTech's products meet the demand for customized products in the industrial IoT industry through the "Lego-style" production model, with a new supply-demand relationship of "low inventory and high fulfillment rate", winning customers at home and abroad. With the new supply and demand relationship of "low inventory and high satisfaction rate", we have won the trust of domestic and foreign customers.

- environmental adaptationDifferent industrial environments have different requirements for the environmental adaptability of RTLS systems. In complex environments such as chemical industry, thermal power plants, coal mines, etc., there are many equipments, complex production sites, and dangerous sources, and there are many interferences to the positioning signals, so the common positioning technology cannot meet the actual needs. WorldTech's ZigBee indoor positioning technology has been carefully designed and optimized to operate stably in various complex environments with good environmental adaptability. For example, in environments with metal and other reflective surfaces, WorldTech's technology effectively avoids the effects of multipath propagation, ensuring accurate and reliable positioning.

- scalability: As organizations grow and businesses expand, RTLS systems need to be scalable to easily adapt to new application requirements and business growth. World Wide Web's WES-RTLS system is highly scalable, allowing users to add additional components at any time, up to company-wide infrastructure, with no additional configuration costs. This gives organizations the flexibility to expand the system as needed to meet changing business requirements in the future.

- Data Security: In industrial production, data security is of paramount importance. RTLS system involves a large amount of location data and production information, which may bring serious losses to the enterprise if leaked or tampered. WorldTech's ZigBee indoor positioning technology focuses on data security, using advanced encryption technology and security mechanisms to ensure data confidentiality, integrity and availability. At the same time, Seiden's system can be integrated with other security systems of the enterprise to jointly build a safe and reliable industrial production environment.

5.2 Advantages of the WorldTech WES-RTLS System

- dexterityWES-RTLS systems are highly flexible and can be adapted to different industrial environments and application requirements. Whether in a large, heavy industrial factory or a small manufacturing plant, the system can be customized and deployed to meet the individual needs of the enterprise. For example, in some factories with limited space, World Power's system can use small and beautiful multi-functional electronic tag reading base station, together with ZigBee acoustic and optical tags, to realize rapid inventory, accurate search or personnel statistics. In some large warehouses, SEEDAN's system can realize real-time monitoring and management of inventory through extended industrial IO and industrial edge computing gateway.

- affordability: The WES-RTLS system from WorldTech provides a cost-effective solution for organizations at an affordable price. Compared with other high-end positioning technologies, WorldTech's ZigBee indoor positioning technology greatly reduces system deployment costs and tag costs while maintaining positioning accuracy and functionality. This makes the advanced real-time positioning system affordable for more enterprises to improve their productivity and management level. At the same time, WorldTech's system is also characterized by low power consumption and low operating costs, which saves enterprises long-term operating expenses.

- dependability: The WES-RTLS system from Seiden Technology has been rigorously tested and validated to be highly reliable. WorldTech products are made of high-quality materials and advanced manufacturing processes to ensure stable operation in harsh industrial environments. At the same time, World Power also provides professional after-sales service and technical support to ensure that the system can be used to solve various problems in a timely manner, so as to ensure that the production and operation of the enterprise will not be affected.

- intellectualize: The WES-RTLS system from WorldTech integrates advanced IoT technology and artificial intelligence algorithms to provide intelligent solutions for enterprises. By analyzing real-time location data, the system can optimize production processes, improve inventory management efficiency, and enhance worker safety and security. For example, the system can help enterprises quickly identify bottlenecks and problems through real-time tracking of work-in-progress, adjusting production plans in a timely manner and avoiding resource wastage. Meanwhile, the system can also improve worker safety and security by monitoring workers' locations and realizing contact tracing and anti-collision functions.

5.3 How to choose the right RTLS system for your organization

- Identify needs: Businesses need to be clear about their needs and goals before choosing an RTLS system. For example, what is the object that the enterprise needs to track? What are the requirements for positioning accuracy? How big is the area to be covered? What is the budget? Only when these requirements are clear, can the enterprise choose the right RTLS system for itself.

- Evaluation techniques: Enterprises need to evaluate different RTLS technologies to understand the advantages and disadvantages of each technology and the applicable scenarios. For example, Bluetooth positioning technology is low-cost and easy to deploy, but the positioning accuracy is relatively low; UWB positioning technology has high accuracy and anti-jamming ability, but the cost is high. Enterprises can choose the most suitable technology according to their needs and budget.

- Inspection of suppliers: When choosing an RTLS system, companies also need to examine the strength and reputation of the supplier. A good supplier should have rich industry experience, professional technical team and good after-sales service. As a global leading IoT product and solution provider, WorldTech has strong technical strength and rich industry experience, and is able to provide enterprises with quality products and services.

- Conducting pilot testsAfter determining the supplier and technical solution of the RTLS system, enterprises can conduct pilot tests to verify the performance and reliability of the system. Through the pilot test, enterprises can find the problems and deficiencies of the system, and make timely adjustments and optimization to ensure that the system can meet the actual needs of enterprises. In conclusion, choosing the right RTLS system requires enterprises to consider a number of factors, including positioning accuracy, cost-effectiveness, environmental adaptability, scalability and data security. With the advantages of flexibility, affordability, reliability and intelligence, World Wide Web's WES-RTLS system is the ideal choice for heavy industrial plants. Enterprises can choose WorldTech's ZigBee indoor positioning technology according to their needs and actual situation to improve their productivity and management level and realize intelligent transformation.

VI. Application of RTLS systems in manufacturing companies

6.1 In-process tracking

- Communicate time and motion data to optimize space and reveal anomalies. In manufacturing, the movement of objects is often complex and difficult to control. WorldCom's ZigBee indoor positioning technology provides organizations with precise location data to help them study how objects are moving. Whether it's a part on a conveyor belt, a work order between stations, or a worker on the move, real-time location data allows companies to understand the patterns behind these moving parts and optimize space layouts. For example, motion history data can reveal anomalies in the normal production process, and timing data can quantify the time required for each stage of production, eliminating the need for workers to manually calculate. Just as the "Taylorism" of factory management has progressed since the late 19th century, Seiden's technology brings new breakthroughs to modern factory management.

- Provide early warning signals to enhance asset visibility. While real-time location data cannot identify all problems, it can enhance asset visibility and make many problems quickly apparent. Examples include a pallet of material inadvertently left at one end of the plant when it is urgently needed at the other end; items on a conveyor belt slowing to half their normal speed; perishable items being shipped ahead of their shelf-life expiration date. WorldCom's ZigBee indoor positioning technology allows organizations to stay on top of these situations and identify problems before early warning indicators become obstacles. For example, when the location of a key piece of equipment remains unchanged for an extended period of time, it could mean that the equipment is malfunctioning, and the system can send out an early warning in time for maintenance personnel to deal with it, avoiding any disruption to production schedules.

- Generate location-based updates to reduce the number of manual scans and processes. Location data can provide affirmative updates, such as marking an item's progress from assembly to quality control, or triggering status updates as manufactured parts advance from one step to another. Location-based work-in-progress (WIP) tracking can provide detailed, real-time pictures showing the progress and sequence of critical processes. WorldTech's ZigBee indoor positioning technology excels in this area, helping to reduce the number of manual scans and required processes, and improving the flow of production. For example, as a part moves from one station to another, the system can automatically update its status without the need for manual scanning.

- Eliminate manual scanning to improve process accuracy and efficiency. Scanning solutions such as barcodes are widely used in manufacturing, but scanning is a manual process that is prone to human error. WorldCom's ZigBee indoor positioning technology reduces errors with automatic real-time updates, making the process more accurate, efficient and agile. In a 30-step manufacturing process, if manual scanning is used to record each step, missing scanning points can cause problems throughout the process if staff don't catch errors immediately. Instead, with WorldTech's system, all key location points between each scan can be mapped, virtually eliminating the scan itself and improving the accuracy and speed of production.

- Identify bottlenecks and breakthroughs and solve problems based on real data. Bottlenecks and roadblocks between the start and finish of a project can be costly. With ZigBee indoor positioning technology from WorldTech, tracking regional-level location data can show the difference in the time it takes for a project to get to different sites. More accurate location data or tracking history can help pinpoint where and when each delay began so that problem-solving plans are based on real data, not just best guesses. For example, in an apparel manufacturing company, if a process is found to have a significant backlog of work-in-process, WorldTech's system can analyze whether it is due to equipment failure or understaffing in that process, etc., so that the problem can be addressed in a targeted way to improve productivity.

6.2 Flexible production and management

- Controlling mobile robots and monitoring part utilization. Numerous innovative companies are considering making traditional production and logistics workflows more flexible and mobile in order to react more quickly to changes in market demand, optimize capacity utilization, or enable smaller batch sizes. WorldTech's ZigBee indoor positioning technology can be combined with flexible, self-organizing production and logistics solutions based on the Siemens SIMATIC RTLS positioning platform to navigate through the material flow, control mobile robots, monitor part usage, and fully archive final product assemblies. For example, in a smart factory, mobile robots can autonomously plan their paths based on the location information provided by Seiden's system to improve efficiency. At the same time, the upper-level system can send control commands to the robot closest to the workstation based on the robot's position information, achieving production optimization.

- Create precise digital twins to provide location information for intelligent automation systems. ZigBee indoor positioning technology from steutech establishes a precise digital twin for all processes, from delivery to further processing to final assembly. The objects in question (e.g. workpieces, tools, automated guided vehicles or robots) are equipped with a positioning tag. The positioning tag signals are collected by an upper-level system, which calculates the position of the signal and provides this information to the intelligent automation system and the production cell. With precise digital twins, the intelligent automation system is able to know the location information of each production process in real time, enabling efficient production management. For example, in the automotive manufacturing process, each component can be tracked by location tags, and the entire process, from raw material delivery to processing to assembly, can be presented in real time in the digital twin, improving production transparency and controllability.

6.3 Worker safety and security

- Contact tracing to help identify people in contact when infection is a problem. In the current work environment, especially in places such as factories, human contact is critical to outbreak prevention and control. Many contact tracking solutions are now in use in manufacturing organizations, with the primary goal of quickly identifying who has been in contact with whom in the event of an infection problem. Contact tracking using WorldCom's ZigBee indoor positioning technology offers significant advantages because real-time location data not only shows the time, location and duration of any person's interactions, but also the amount of time an individual spends in between those interactions. For example, during an outbreak, a manufacturing organization can monitor employee location information in real time by equipping them with tags with WorldTek's location-enabled tags. Once an employee is found to be infected, the system can quickly identify those who have had close contact with the employee during a specific time period so that timely testing and quarantine measures can be taken to effectively prevent the spread of the outbreak.

- Collision prevention, providing real-time data, combined with other safety measures. Workplace accidents cost factories a great deal of money each year, with collisions being one of the main perpetrators. Existing safety measures include bright signage, audible alarms for vehicle or personnel movement, indoor traffic lights, deployable safety buffers, extensive training, and protective gear for individual workers. WorldTech's ZigBee indoor positioning technology, however, provides real-time data that can better inform the use of other safety measures. For example, in cross-space high-altitude synchronous operations, a fully automated collision avoidance system based on synchronous fusion of multi-source information is used, integrating an infrared laser positioning system, automatic positioning limits and visual system identification, to automatically monitor and identify the entire process of anti-collision monitoring and warning for group towers and crawler cranes operating in relative space synchronization. By arranging infrared laser emitters and detectors and their infrared laser positioning modules on key structural positions of tower cranes, the time or phase difference of infrared reflected signals is calculated to know the exact position of the equipment. At the same time, high resolution cameras and their visual recognition modules installed on the tower crane from multiple angles are able to recognize the components of the crane, its operation status and possible obstacles on the site. The automatic limit switches in the automatic limit subsystem are mounted directly on the crane at critical locations to monitor the operating status of the equipment and warn of approaching preset limits or directly trigger a shutdown program. The central processing unit coordinates the exchange of data between the subsystems and receives data inputs from the sensors, performs data integration and advanced decision processing, and issues control commands to the appropriate actuators. In manufacturing companies, when vehicles and workers approach each other along cross corridors, WorldTech's systems can trigger lights to come on, or audio warnings to appear, or tactile alarms on workers to avoid collisions.

- Identify congested or hazardous areas to prevent collisions. An important part of collision prevention is identifying where accidents are likely to occur. WorldCom's ZigBee indoor positioning technology can use real-time location data to identify congested or dangerous areas and provide early warning to prevent collisions. For example, in employee location tracking, by equipping each employee, contractor or site visitor with a tag, their precise location can be identified in real time. The geofencing feature allows any number of virtual zones to be set up to represent geographic boundaries and automatically trigger a response when a tracking tag enters or leaves an area. When a person enters a warning area, an IO link-enabled beacon can signal a possible hazard and alert the facility manager about the violation. If a person continues to enter a hazardous area, machines that pose a threat to the person's health are automatically stopped, preventing any threat of injury. Dynamically labeled areas can be alerted, reported and tracked based on the proximity of two moving entities and the duration of their encounter. When a person is walking along an aisle and a forklift approaches them from around a corner, dynamic labeling zones make these entities located around the corner or behind the aisle "visible" to each other and can alert them to prevent accidents or fatal injuries. Additionally, indoor foot traffic analysis can show movement density and flow through foot traffic heat maps and spaghetti diagrams, which help visualize flow patterns and show analysis of the movement and interaction of people and things in a physical space. They reveal dwell time patterns and highlight wait times so that operational efficiencies can be improved through process, space and workflow optimization, as well as identifying congested areas that may be at risk of collision.

VII. Case studies of RTLS systems in manufacturing companies

Take the WES-RTLS system of WorldTech as an example to show its practical application effect in manufacturing enterprises. Including successful cases of improving production efficiency, optimizing process management, and enhancing safety.

7.1 Successful cases of productivity improvement

In a large automobile manufacturing enterprise, the WES-RTLS system of World Power Technology was introduced. Through the real-time tracking of WIP by the system, the enterprise can accurately grasp the position of each part on the production line, adjust the production plan in time to avoid resource wastage. For example, when the system detects a backlog of WIP in a process, it will automatically issue an early warning so that managers can quickly analyze the cause, which may be due to equipment failure or understaffing. By timely deploying maintenance personnel or increasing manpower, bottlenecks are effectively solved and production efficiency is improved. At the same time, the movement history data and timing data provided by Seiden's ZigBee indoor positioning technology helped the company optimize the production layout, reduce unnecessary handling and waiting time, and further improve production efficiency.

7.2 Successful cases of optimized process management

An electronics manufacturing company has achieved comprehensive monitoring of its production processes with the use of the WES-RTLS system from Seiden Technologies. Location data can provide affirmative updates, such as marking the progress of an item from assembly to quality control, or triggering status updates as manufactured parts advance from one step to another. Location-based work-in-progress (WIP) tracking provides a detailed, real-time picture of the progress and sequence of critical processes. This enables companies to identify inefficiencies in their processes in time for targeted optimization. For example, in the manufacturing of electronic products, through real-time tracking of WIP, the enterprise found that the manual scanning link of a certain process was time-consuming and prone to human error. As a result, the enterprise adopted WorldTech's ZigBee indoor positioning technology, which realized automatic real-time updates, reduced errors, and improved the accuracy and efficiency of the process. At the same time, the system also helped the enterprise reduce the number of manual scans and required processes, improving the smoothness of production.

7.3 Successful cases of security enhancement

At a mega-engine manufacturing company, WorldTech's WES-RTLS system provides worker safety. Contact tracing helped the organization quickly identify who had contact with whom in the event of an infection. During an outbreak, companies equip their employees with tags with World Power's locator function to monitor their location information in real time. Once an employee is found to be infected, the system can quickly identify those who have had close contact with the employee during a specific time period so that timely testing and isolation measures can be taken to effectively prevent the spread of the outbreak. The anti-collision function also plays an important role. In the cross-space high-altitude synchronous operation, a fully automatic anti-collision system based on the synchronous fusion of multi-source information is used, integrating the infrared laser positioning system, automatic limit and visual system identification, and the whole process of automatic monitoring and identification of group towers and crawler cranes relative to the spatial synchronous operation of the anti-collision monitoring and early warning. The real-time data provided by WorldTech's ZigBee indoor positioning technology better informs the use of other safety measures. When vehicles and workers approach each other along cross corridors, the system can trigger lights to come on, or audio warnings to appear, or tactile alarms on workers to avoid collisions. Additionally, the ability to recognize crowded or dangerous areas gives advance warning of possible collisions. By equipping each employee with a tag, their precise location can be identified in real time. The geo-fencing feature allows any number of virtual zones to be set up to represent geographic boundaries and automatically triggers a response when a tracking tag enters or leaves an area. When a person enters a warning area, an IO link-enabled beacon can signal a possible hazard and alert the facility manager about the violation. If a person continues to enter a hazardous area, machines that pose a threat to a person's health are automatically stopped, preventing any threat of injury.

An electronics manufacturing company has achieved complete monitoring of its production processes with the use of the WES-RTLS system from Seiden Technologies. Location data can provide affirmative updates, such as marking the progress of an item from assembly to quality control, or triggering status updates as manufactured parts advance from one step to another. Location-based work-in-progress (WIP) tracking provides a detailed, real-time picture of the progress and sequence of critical processes. This enables companies to identify inefficiencies in their processes in time for targeted optimization. For example, in the manufacturing of electronic products, through real-time tracking of WIP, the enterprise found that the manual scanning link of a certain process was time-consuming and prone to human error. As a result, the enterprise adopted WorldTech's ZigBee indoor positioning technology, which realized automatic real-time updates, reduced errors, and improved the accuracy and efficiency of the process. At the same time, the system also helped the enterprise reduce the number of manual scans and required processes, improving the smoothness of production.

An electronics manufacturing company has realized comprehensive monitoring of its production processes with the use of the WES-RTLS system from Seiden Technologies. Location data can provide affirmative updates, such as marking the progress of an item from assembly to quality control, or triggering status updates as manufactured parts advance from one step to another. Location-based work-in-progress (WIP) tracking provides a detailed, real-time picture of the progress and sequence of critical processes. This enables companies to identify inefficiencies in their processes in time for targeted optimization. For example, in the manufacturing of electronic products, through real-time tracking of WIP, the enterprise found that the manual scanning link of a certain process was time-consuming and prone to human error. As a result, the enterprise adopted WorldTech's ZigBee indoor positioning technology, which realized automatic real-time updates, reduced errors, and improved the accuracy and efficiency of the process. At the same time, the system also helped the enterprise reduce the number of manual scans and required processes, improving the smoothness of production.

An electronics manufacturing company has realized comprehensive monitoring of its production processes with the use of the WES-RTLS system from Seiden Technologies. Location data can provide affirmative updates, such as marking the progress of an item from assembly to quality control, or triggering status updates as manufactured parts advance from one step to another. Location-based work-in-progress (WIP) tracking provides a detailed, real-time picture of the progress and sequence of critical processes. This enables companies to identify inefficiencies in their processes in time for targeted optimization. For example, in the manufacturing of electronic products, through real-time tracking of WIP, the enterprise found that the manual scanning link of a certain process was time-consuming and prone to human error. As a result, the enterprise adopted WorldTech's ZigBee indoor positioning technology, which realized automatic real-time updates, reduced errors, and improved the accuracy and efficiency of the process. At the same time, the system also helped the enterprise reduce the number of manual scans and required processes, improving the smoothness of production.

In conclusion, the practical application of WorldTech's WES-RTLS system in manufacturing enterprises is remarkable, providing strong support for enterprises to improve production efficiency, optimize process management, and enhance security.

VIII. Prospects for RTLS systems in manufacturing companies

8.1 Market Size Projections

The Real-Time Location Systems (RTLS) market is witnessing strong growth and this trend is well reflected in several market research reports. For example, the "Real-Time Location Systems (RTLS) Market Outlook and Industry Scale Research Report 2024" states that the global Real-Time Location Systems (RTLS) revenue, in terms of revenue, will be approximately $4,662.1 million in 2023, and is projected to reach $18,970 million in 2030, with a compound annual growth rate (CAGR) of 22.21 TP3T. Real-Time Location System (RTLS) Industry Growth Opportunities and Competitive Risks Research Report 2024" also indicates that the global Real-Time Location System (RTLS) market size is expected to reach 385,668 million yuan by 2029, with a CAGR of 33.25%. In the Chinese market, "China Real-Time Location System (RTLS) Industry Sales Scale Analysis Report - Behind The Scenes" predicts that the global Real-Time Location System (RTLS) revenue will reach approximately 4662.1 million yuan by 2027, with a CAGR of 18970 million yuan. In China market, "China Real-Time Location System (RTLS) Industry Sales Scale Analysis Report - Behind the Scenes" predicts that the global RTLS market will reach 162.916 billion yuan by 2027, while "Real-Time Location System (Rtls) Market Development Status and Outlook Research Report - GlobeNewswire" mentions that the China RTLS market will reach 17.637 billion yuan by 2023, and it is expected that the global RTLS market volume will reach 2.62% with a CAGR of 33.25%. 26.72% CAGR to reach $259,354 million by 2029. These figures fully demonstrate the huge potential and broad development prospects of the real-time positioning system market.

8.2 Distribution of Major Enterprises and Regions

The Global Real-Time Location Systems Market has a large number of major vendors covering different product types and applications. Vendors such as West, Stanley Healthcare, Ekahau, Zebra Technologies, CenTrak, IBM, Intelleflex, Awarepoint Corporation, Midmark RTLS, TeleTracking, Ubisense Group, Savi Technology, Identec Solutions, AiRISTA, Sonitor Technologies, Elpas, Axcess International, Essensium, GE Healthcare, TimeDomain, BeSpoon, Intelligent Insites, Mojix, PINC Solutions, Plus Location Systems, Radianse, RF Technologies, ThingMagic, Locaris, SCHMIDT, KINGDOES, Catapult Sports, Statsports, etc. are the major players in the global Real Time Location Systems (RTLS) industry.

In terms of regional distribution, North America, Europe, and Asia Pacific are the major markets. North America holds a large market share, as indicated in the "Real-Time Location System (RTLS) Industry Growth Opportunities and Competitive Risks Research Report 2024", North America is the largest Real-Time Location System (RTLS) market, with a market share of approximately 40%. In North America, the key countries include the U.S., Canada, and Mexico. The United States Real-Time Location Systems (RTLS) market volume, sales and growth rate have a significant impact on the overall North America regional market. The European region market also has an important position, Germany, the United Kingdom, France, Italy, Scandinavia, Spain, Belgium, Poland, Russia, Turkey and other countries with different market performance. The Asia-Pacific region, as an emerging market, has greater development potential, and China is one of the major consumer markets in the Asia-Pacific region. The report "Domestic Real Time Location System (RTLS) Market Development Overview Report - Mobile Sohu.com" mentions that industry players can use the report to identify the major market agglomerations in the Real Time Location System (RTLS) industry, regional market changes brought about by carbon neutrality, and make timely adjustments to the domestic market layout, focusing on the markets with the highest demand, the strongest support for carbon neutrality, and the most potential. In addition, the markets of Japan, Australia and New Zealand, India, ASEAN, South Korea and other countries are also developing.

8.3 Trends in industry development

With the advancement of Industry 4.0 and digital transformation, RTLS systems will be more widely used in manufacturing enterprises. As mentioned in "Real-Time Location Systems Enabling Industry 4.0 | Seizing the Opportunity of the Age | iot | Artificial Intelligence |", with the advent of Industry 4.0 and the rapid adoption of technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) that are making headlines in the media and in manufacturing and logistics, we are witnessing a boom in the digitization of industry as a result. The maturity of the digital twin has been greatly aided by the growing adoption of location and context-aware technologies, such as real-time location systems (RTLS) and the Internet of Things (IoT).

The technology of RTLS systems continues to advance, bringing more value to the manufacturing industry. For example, the use of Ultra Wideband (UWB) technology enables manufacturing organizations to locate objects with centimeter-level accuracy, improving productivity and management. WorldTech's ZigBee indoor positioning technology also has unique advantages, which guarantees positioning accuracy while featuring low cost, low power consumption, large network size, and self-organizing network. WorldTech's WES-RTLS system can provide manufacturing enterprises with more flexible and affordable real-time positioning solutions to meet the needs of different enterprises.

In the future, the RTLS system will be combined with other advanced technologies, such as artificial intelligence and big data, to provide more intelligent solutions for manufacturing enterprises. For example, by analyzing real-time location data, production processes can be optimized, inventory management efficiency can be improved, and worker safety and security can be enhanced. In addition, with the global focus on carbon neutrality goals, RTLS systems will also play an important role in energy saving and emission reduction, contributing to the sustainable development of manufacturing companies. In response to the global trend of sustainable development, WorldTech will continue to optimize and upgrade its ZigBee indoor positioning technology to provide more environmentally friendly and efficient solutions for manufacturing enterprises. (END)

Editor-in-Chief:Ameko Wu

Content Reviewer:Jimme Yao

Content Reviewer:Jimme Yao