I. Industry status and needs

The intelligent management system and safety system of the power plant are very important, the use of advanced Internet of Things, the Internet, artificial intelligence and other advanced technologies to achieve the equipment layer, the control layer, the production supervision layer of the state of the supervisory level of data collection and the data of the various levels into the central core of the management system, to achieve the ultimate goal of the intelligent integration of the production of the power plant. In the safety system, Hainan Shidian's UWB-based high-precision location information management system can solve the following pain points commonly found in power plants:

Pain point 1: The daily inspection work of the staff in the production area is relatively backward in management, and the traditional inspection is recorded and controlled through manual registration at the inspection points. Inspection information can not be shared in real time to the department, the management can not grasp the inspection status in real time, there are cases of missed inspection.

Pain point 2: The staff on duty in the production area can not be quickly assessed, the traditional attendance is carried out by swiping the card, and can not effectively monitor and statistics on the on-duty data, personnel distribution and so on.

Pain point 3: The power plant will carry out maintenance work for the units in a planned manner, which requires a large number of outsourced personnel to carry out operations such as cleaning, earth moving, maintenance, etc. The lack of effective supervision and statistical means for the safety control and time attendance of the outsourced personnel is a big safety hazard and inaccurate data statistics.

Pain point 4: The personnel positioning management system is linked with various supervisory and monitoring subsystems to realize information interconnection and resource sharing, and ultimately realize the fine management of the power plant.

II. Overall programmatic structure

The system includes UWB tag, UWB explosion-proof base station, positioning engine software (C/S architecture) and positioning application system. Positioning tags and positioning base station communicate through UWB pulse signals. The positioning base station transmits the received positioning tag data to LS1000 positioning engine through 5G network and wired Ethernet for data analysis and processing, and transmits the processed accurate position to the upper layer application through an open API interface.

The system components are as follows:

- UWB tags: card-type and wristband-type, fixed on top of the person or object to be located, can periodically transmit UWB signals with tag ID information.

- UWB outdoor wired base station: communicates with the positioning tags and transmits information back to the positioning engine algorithm software;

- Positioning engine algorithm software: locally deployed, the underlying information data is collected and processed through the algorithm of the positioning engine to get the accurate coordinates of the positioning tag.

- Positioning application software: locally deployed or cloud deployed, the application layer software realizes the basic functions such as positioning display, track playback and other functions, as well as the business functions such as electronic fence, intelligent inspection, attendance statistics and video linkage based on the expansion of location data.

III. Programmatic functions

|

function point |

Functional Description |

|

Real-time positioning of personnel |

Realize real-time positioning management for power plant operators, third-party operators, inspectors and visitors, view the real-time location of the located personnel, distribution areas and other information, and grasp personnel dynamics at any time and any place.

|

|

Regional staffing statistics |

Real-time counting of the number of people in each area, e.g. main plant, booster station, boiler 0m level, chemical water plant, ammonia station, etc.

|

|

Historical track search |

The visualized traceability of overhaul operations can be achieved by playing back historical trajectories and organically combining spatio-temporal information with operational content and video images.

|

|

electric fence |

Based on the overhaul tasks, set up virtual job fences to supervise the scope of the overhauler's work and the time of the work. Associate the tasks of maintenance personnel with time and space. Set alarm fences for the charged operation area during maintenance, and generate alarm messages on the supervision platform once non-authorized personnel intrude into the area.

|

|

Alarm type |

Entering the restricted area alarm: Restriction of dangerous areas, unauthorized personnel to enter the alarm will be issued, in the access to certain gates, can be set up to pass the conditions, when not in line with the requirements of the personnel in and out of the gates will be issued an alarm message; or certain areas can only be accessed at specific times, such as in other periods of time to enter the area will be regarded as illegal trespassing, but also will be issued an alarm. Stall Alarm: When the maintenance personnel in the specified time, did not leave the operation area in time to reach a certain time, issued an alarm message. SOS Alarm: When an accident occurs on the scene and emergency assistance is needed, the SOS button on the label can be triggered to initiate a distress message to the platform.

|

|

on-the-job attendance |

According to the set operation attendance area, it automatically counts the time, number of people on duty and working hours of power plant operators, third party personnel and inspection personnel. The management can quickly check the on-duty situation, and the monthly statistics of working hours can also be directly based on the platform data as an audit reference for attendance. |

|

Intelligent Inspection |

Customize the planning of inspection points and inspection routes, set the inspectors and cycle, and the real-time location of the inspections of the operators and inspection tasks through the platform way to show and share out, the management can real-time view of the completion of the inspection tasks, inspection records and the time, space corresponding information can be automatically entered into the management system, convenient to do the work of summarizing and problem tracing to meet the full range of electric power and energy industry timed inspections Demand.

|

|

One-click evacuation |

The platform can send a one-click evacuation reminder to all the tags in a customized area, and the tags will remind people in the area to evacuate urgently through vibration and beeping.

|

|

Integration of the two votes |

Integration with the two-ticket system, linking the access control within the area, automatic authorization and authority recovery according to the start time and end time of the operation. At the same time, it can push the risk information of the area to the relevant operators for risk pre-control.

|

|

video link |

Combining the UWB positioning system with the video monitoring system of the power plant, once an early warning occurs in a certain area, such as strangers appearing at entrances and exits, personnel entering the area without authority, personnel approaching the source of danger, and personnel asking for help, etc., the system will immediately pop up the on-site monitoring screen and take photographs to record the on-site situation, so as to provide a basis for efficient decision-making. |

IV Actual project case demonstration

Project Name: A power plant project in Taizhou

Project requirements: positioning of visitors, operations, inspections, etc.

Function: Upload the real-time location data of visitors, operation and inspection personnel to the intelligent power plant management platform, and realize various functions such as access rights, operation attendance, personnel statistics, security alarms, inspection tasks and so on.

Project Scope: Multi-unit area, main plant multi-story, main transformer booster station, fuel area, boiler

Number of base stations: approximately 1,000, targeting 1,000 people

Networking: wired and 5G

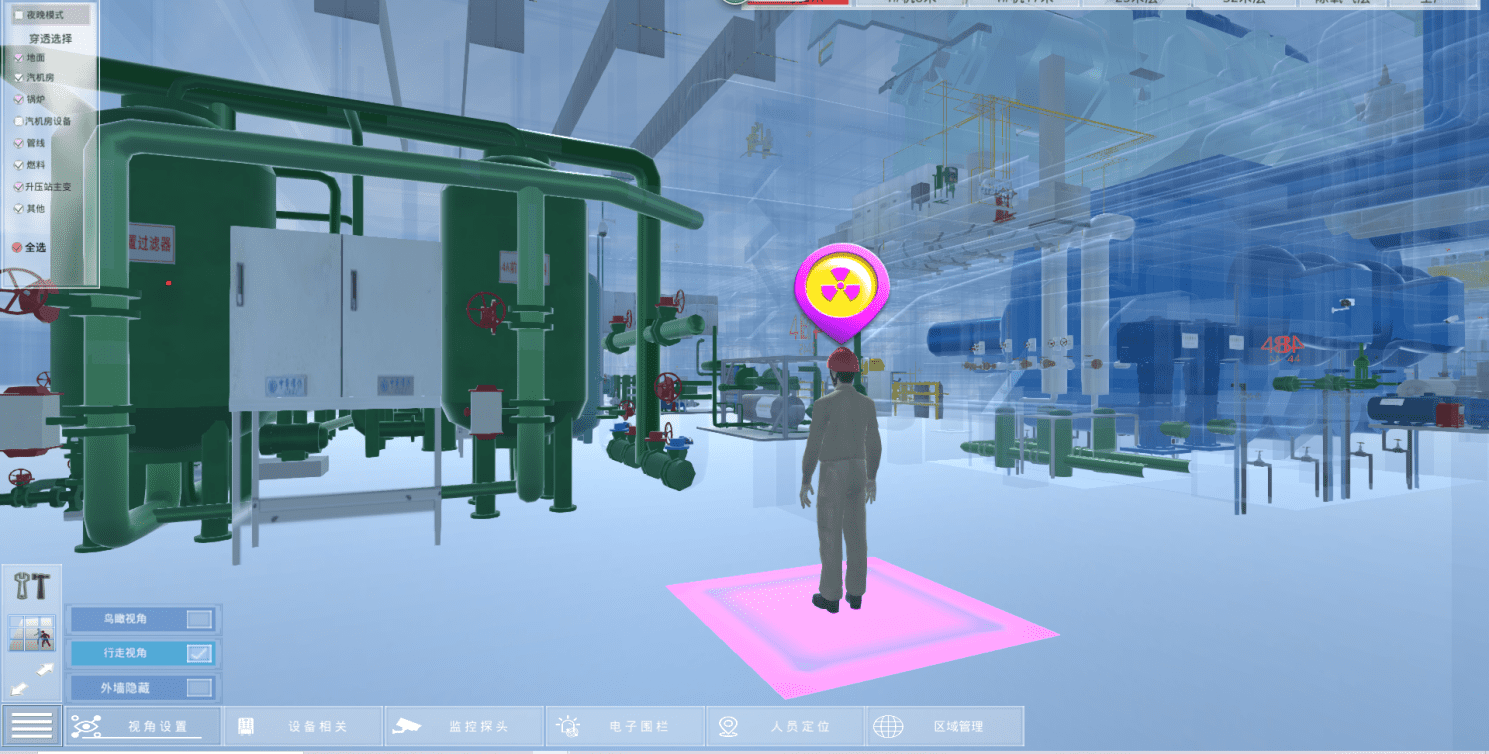

Positioning engine rendering

Three-dimensional positioning effect

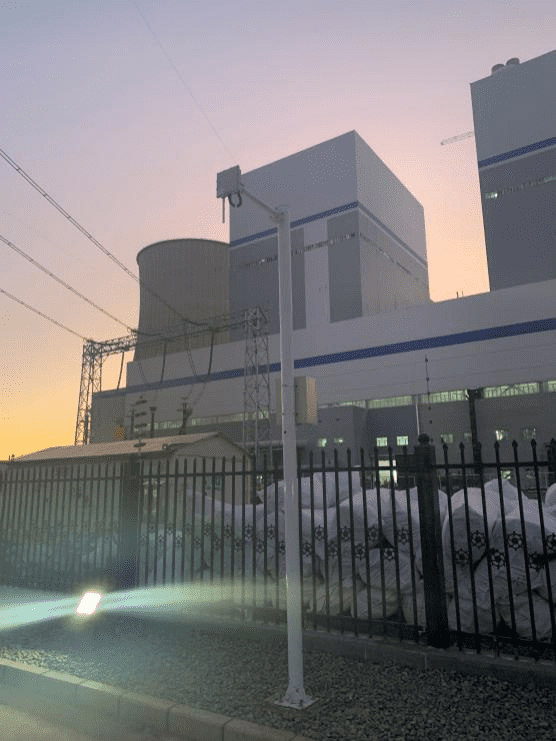

Base station site installation photos

Content review.