It is common in industry to need to measure various types of non-electrical physical quantities that requireVarious sensorsTo obtain, for example, temperature, pressure, speed, angle, etc., which need to be converted into analog electrical signals in order to be transmitted to a control room or display device hundreds of meters away. There are many industrialcommunication protocolrespond in singingcommunications interfaceThe most widely used way to transmit analog data is to use 4 to 20 mA current, and the most widely used way to transmit analog data is to use 4 to 20 mA current.International Electrotechnical Commission (IEC)Analog signal transmission standard used in process control system. Our country also adopts this international standard signal system, the instrument transmission signal using 4-20mA.DC, receiving signal using 1-5V.DC, that is, using current transmission, voltage receiving signal system.

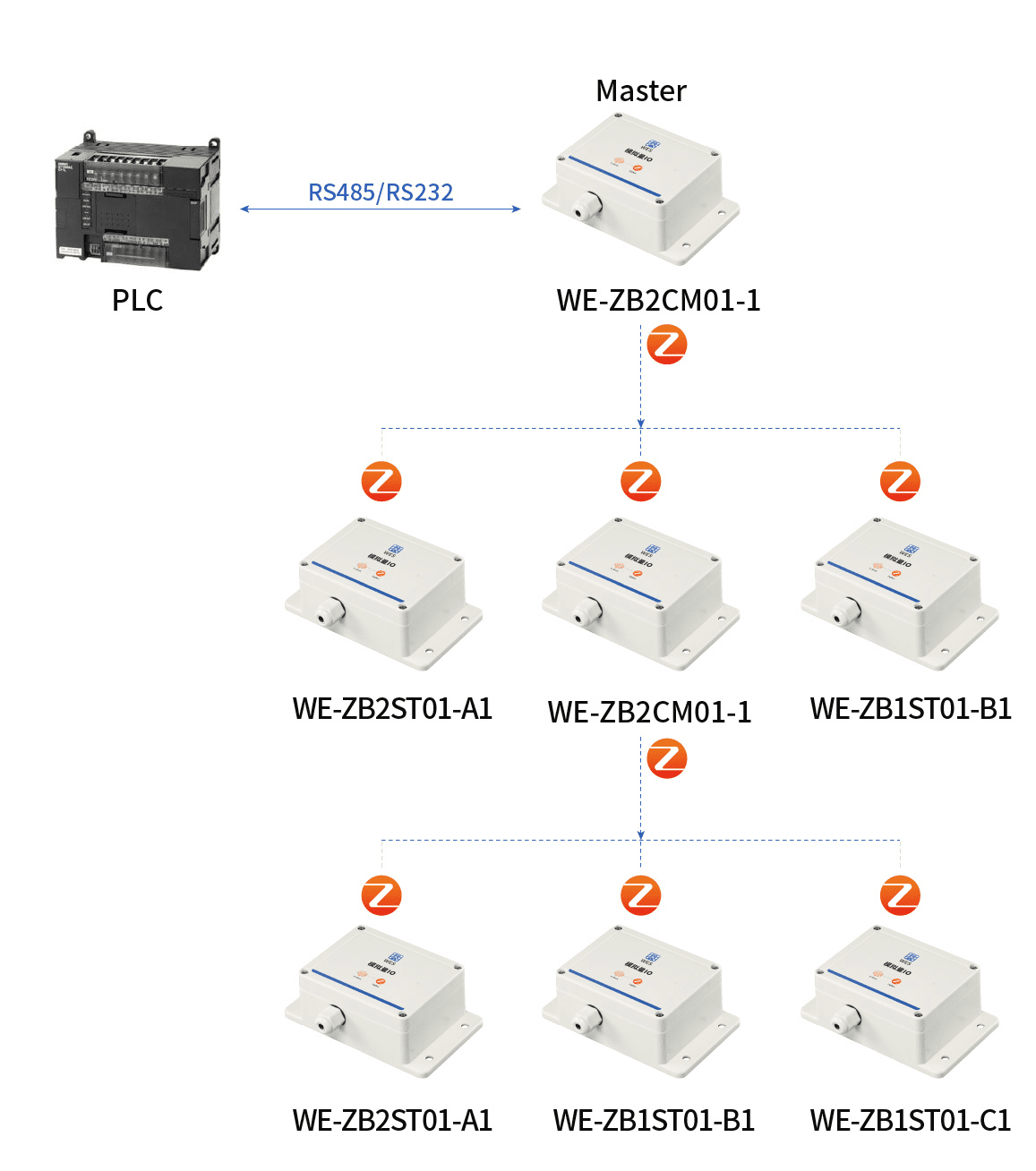

World PowerdevelopedWE-ZB1ST01Series and ProductsWE-ZB2ST01Series wireless analog IO devices, support 4-20mA current signal, there are different models in this series of products, such as input and output, single input and single output, please refer to the following list, the series of products are officially launched in June.

| model number | descriptive |

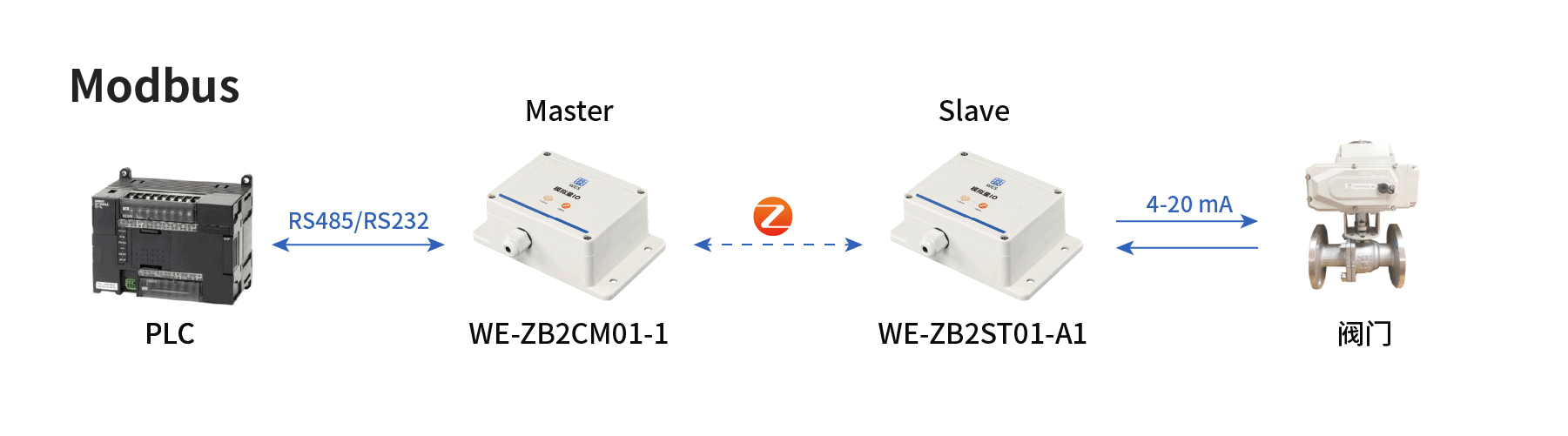

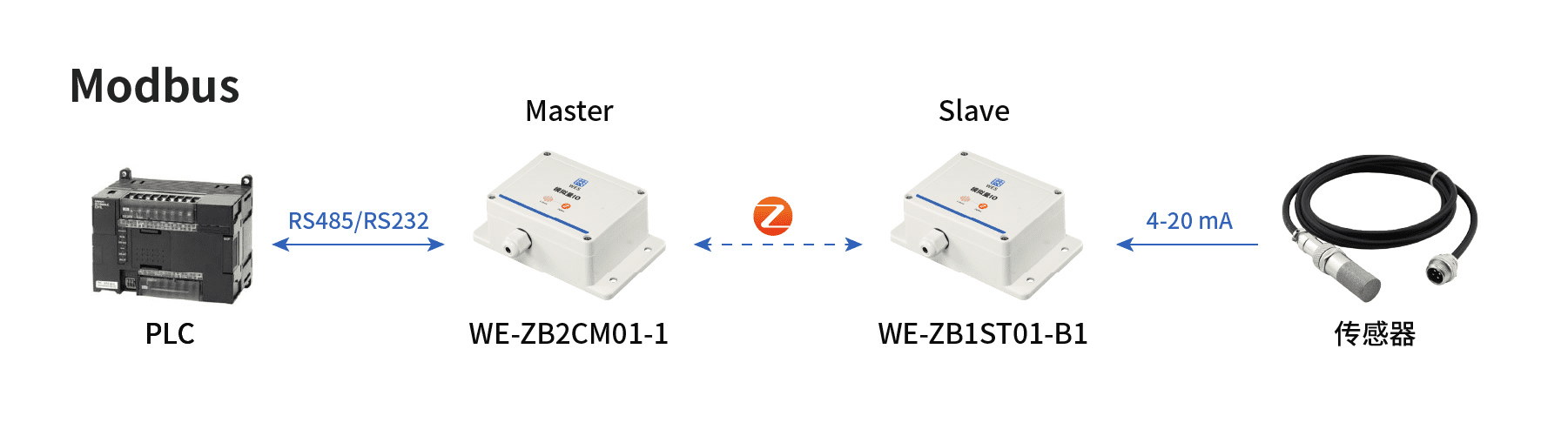

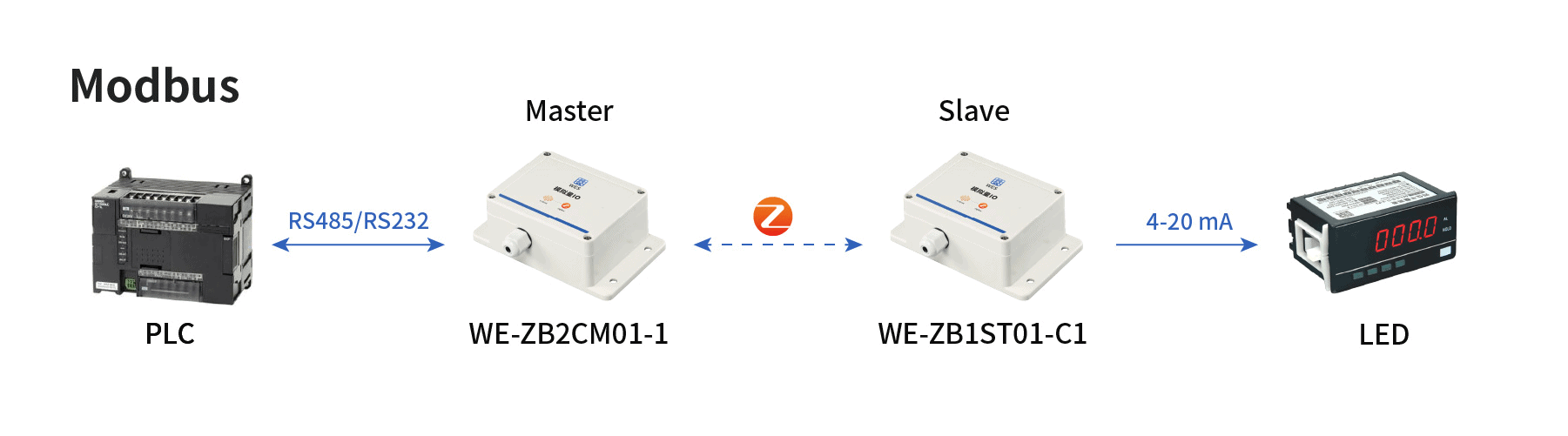

| WE-ZB2CM01-1 | RS-485 to Digimesh as Modbus master role (under development) |

| WE-ZB2ST01-A1 | Input and output functions, supporting standard Modbus-RTU protocols |

| WE-ZB1ST01-B1 | Single input function, supports standard Modbus-RTU protocols |

| WE-ZB1ST01-C1 | Single output function, supports standard Modbus-RTU protocols |

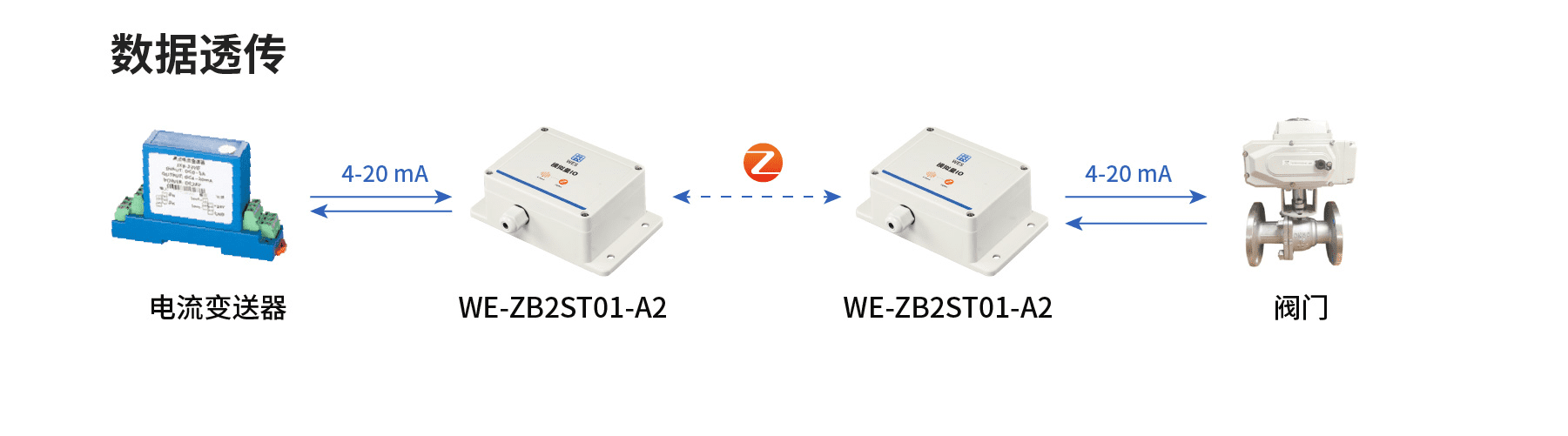

| WE-ZB2ST01-A2 | Input and output functions, data passthrough |

| WE-ZB1ST01-B2 | Single input function, data passthrough |

| WE-ZB1ST01-C2 | Single Output Function, Data Passthrough |

naming convention::

CM:Gateway connectivity class of equipment

ST: Sensors and other terminal equipment

01:Series No.

A/B/C: Hardware version

1/2 : represents the firmware difference, 1: modbus protocol; 2: analog transmissions

Product Features

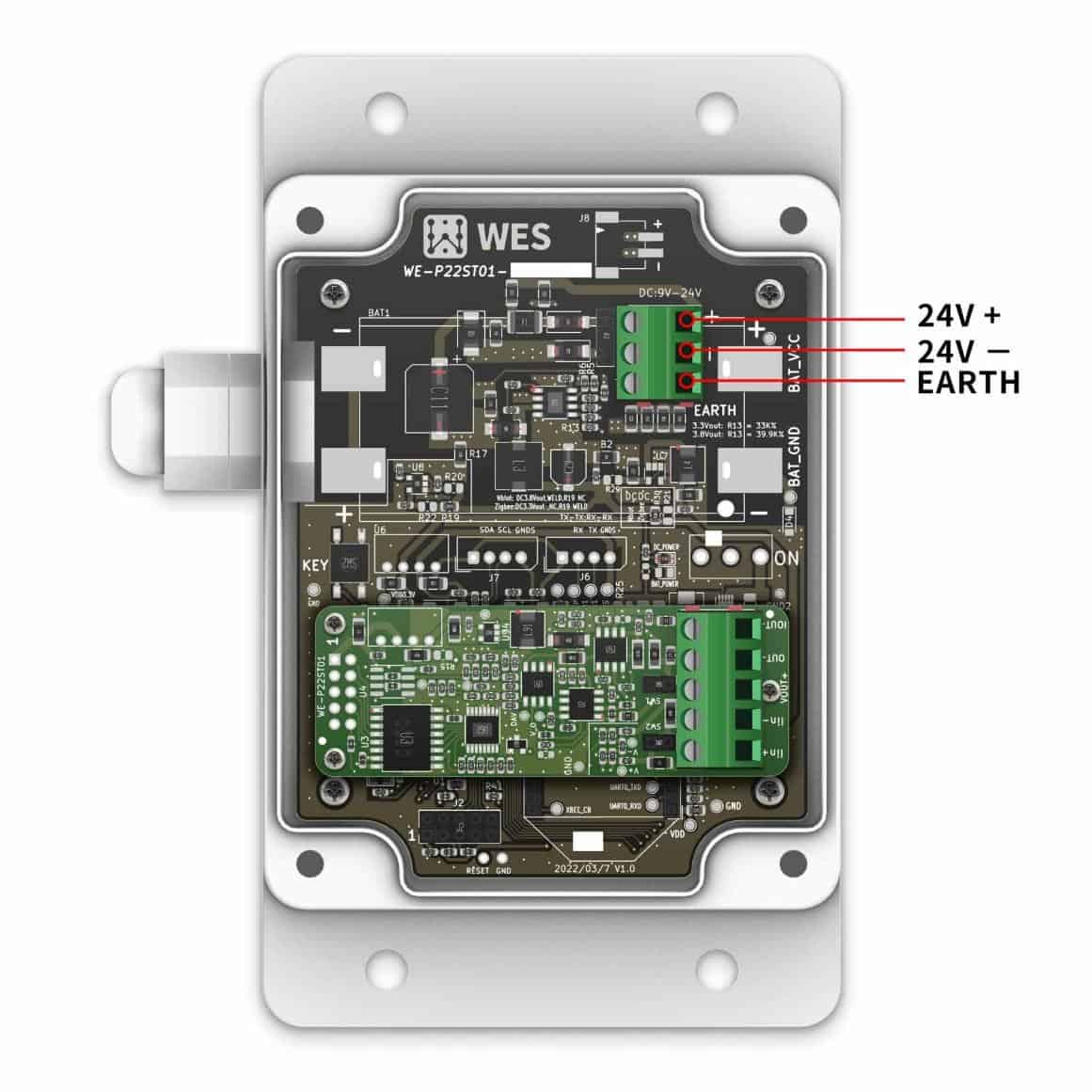

(1) Wide voltage supply 9 to 24V;

(2) Measuring range 4-20mA;

(3) Accuracy class 0.1%;

(4) Supports standard Modbus-RTU protocol or data passthrough;

(5) The wireless module uses Digi's Xbee module, and uses the DigiMesh method of networking;

(6) Provides keys for restoring factory settings;

(7) Support high protection level, including signal protection, interface protection and power protection;

(8) The product is easy to install and use, easy to operate with the upper computer, and can realize rapid networking.

Application Areas

WE-ZB1ST01 AD acquisition adopts capacitive isolation technology to ensure that the sampling accuracy is not interfered by external signals, which has the advantages of high accuracy, safety and reliability, ease of use, etc. It is suitable for industrial application scenarios, such as petroleum, chemical industry, intelligent factories and automation systems. The product is easy to install and use, and convenient to operate with the upper computer, which can realize rapid networking and build a monitoring system.

Commonly used application areas:

- Unattended weighing: Using a serial server, you can connect related serial devices such as weighing meters, receipt printers, road gates and other weighing equipment to the LAN.

- Unattended weather station: through the monitoring of wind direction, wind speed, temperature, humidity, air pressure, rainfall, soil temperature and humidity of various types of sensors sent to the network equipment

- Remote Attendance: Attendance machine plus serial server, can transfer attendance data to the server

- Remote control PLC: PLC to increase the serial port server, cloud server and local programming software combined with the virtual serial port, so as to realize the remote programming to the PLC

- Intelligent construction site tower crane monitoring: real-time wireless transmission of machinery above the tower crane operating status on each construction site, combined with data acquisition and fusion processing technology to reduce safety hazards

- Intelligent city flood monitoring system: real-time collection of rainfall and water level information in culverts, transmitted to the network through the server for timely processing

Device Connection Method

Product Information

Content review.