I. Background of coal mine safety monitoring system design

Coal resources have always occupied a dominant position in China's entire energy structure system. However, due to the complexity of the coal mining environment, all kinds of safety accidents often occur in the process of coal production, posing a serious threat to the health and even life of mine workers. At the present stage, higher requirements have been put forward for all aspects of coal mine production. Based on this, safety monitoring systems are set up in the mines, which are used to monitor the technical parameters in the mines in real time, in order to find and deal with problems in time, and to avoid serious safety accidents caused by small problems.

II. Introduction to coal mine safety monitoring system

Based on the analysis of the actual situation of the mine, the overall scheme of the coal mine safety supervision system is designed and studied: the system is mainly composed of personnel positioning system, production equipment supervision system and mine environment monitoring system. Through the design and practical application of the coal mine safety supervision system, it is found that the system can monitor and analyze the personnel, equipment and environmental parameters in the mine in real time in order to master the operation of the mine. If there are potential safety hazards underground, the system will issue sound and light alarms and take corresponding control measures. The system has achieved good practical application results, effectively guaranteeing the safe production of the mine and obtaining good safety benefits.

III. Overview of the coal mine safety monitoring system design program

The factors that pose a threat to safety in the process of coal mine production are multifaceted, and based on the full study of the actual situation of coal mine production, these factors can be divided into three major categories, which are personnel safety, production equipment completely and environmental safety. Figure 1 shows the schematic diagram of the overall program of the designed coal mine safety supervision system. It mainly utilizes various types of sensors and video monitoring equipment to monitor the activities of underground personnel, the state parameters of production equipment and the environmental parameters of the mine in real time, obtain the corresponding text, voice and video data information, and utilize the industrial Ethernet to collect and transmit the data information to the mine safety monitoring system located on the ground. The acquired data information is transmitted to the measurement and control center located on the ground. After the measurement and control center obtains the data information, it will be stored in the database server, and at the same time, it is also necessary to share the information with the management personnel who have the authority, and most importantly, it is necessary to analyze and process the data information, judge the working status of the mine, and guarantee the safety of coal mine production.

Fig. 1 Schematic diagram of the overall scheme of the coal mine safety supervision system

IV. Introduction to coal mine safety monitoring systems

The designed coal mine safety supervision system mainly contains three major sub-systems, which are personnel positioning system, production equipment monitoring system and environmental parameter monitoring system, and the three sub-systems are described in detail below.

1. Personnel locator system

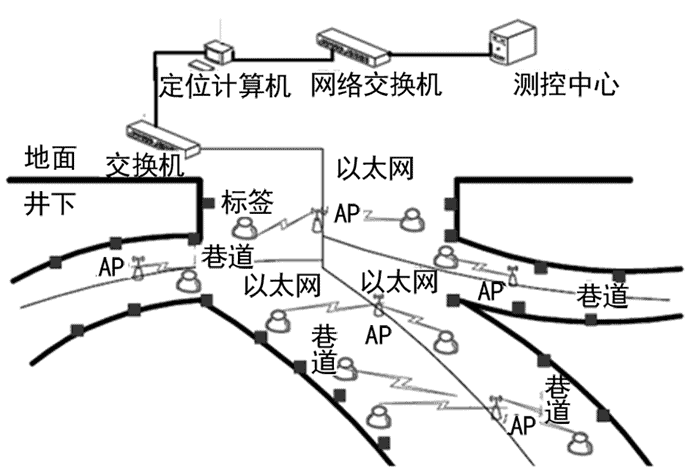

The most important thing of coal mine safety supervision system is to ensure the safety of underground personnel. Therefore, personnel positioning system is the most important of all systems, as shown in Figure 2 for the basic principle diagram of personnel positioning system. Fixed tags are set up at each location in the mine, and all personnel carry identification cards. The connection between the identification card and the fixed tag is established through the AP wireless network. Through the tag, the location information of underground personnel can be obtained and transmitted to the measurement and control center through industrial Ethernet to analyze and judge the specific location of underground personnel. In addition to the above functions, through the personnel positioning system, the monitoring personnel on the well can also shout to the underground personnel through the walkie-talkie, so that they can communicate with the underground personnel in case of emergency. The personnel location information detected by the system will be displayed in real time on the monitoring screen in the measurement and control center, and the management personnel can grasp the specific location of all personnel in real time through the monitoring screen. The personnel positioning system can be used for attendance in daily management, and the system can be used for emergency rescue in case of emergency.

Figure 2: Basic principle diagram of the personnel locator system

2. Production equipment monitoring system

Condition monitoring of major coal mining equipment is an important measure and means to ensure the safety of coal mine production equipment. In order to ensure the reliability and stability of data information transmission, data transmission is carried out through wired network for mechanical equipment with basically fixed position, such as belt conveyor, ventilator, etc., and data transmission is carried out through 900M wireless network (ZigBee or LORA) for mechanical equipment that needs to be constantly moved, such as coal mining machine, roadheader, etc. The data information to be collected mainly contains two aspects, one is the power consumption data of mechanical equipment, such as power supply voltage, current and power, etc.; and the other is the operation status of key mechanical parts, such as bearing temperature, motor temperature, etc. Considering the large number of electromechanical equipments in the mine, it is necessary to set up monitoring sub-system for each electromechanical equipment. Especially for some key electromechanical equipment, such as ventilators, real-time monitoring function must be realized. All the data information obtained from monitoring needs to be transmitted to the ground measurement and control center for analysis and processing, in order to judge whether the working status of the equipment is normal or not.

3. Environmental parameter monitoring systems

The working environment of a mine is very complex, and contains a large amount of dust, gas, CO and other toxic and hazardous gases, which may affect the physical and mental health of underground workers, or cause serious accidents such as fires and explosions, which may threaten the safety of workers. The safety monitoring system is based on the installation of different types of sensors in the working face of the mine, in the roadways, in the refuge rooms, etc. The sensors are used to monitor the relevant environmental parameters, such as the wind speed, the gas concentration, the CO concentration, the gas pressure, the temperature, etc. The data obtained from the sensors is passed on to the mine operator and is used to monitor the safety of the workers. The data from the sensors is transmitted to the ground control center via the underground sub-station and the industrial Ethernet network. After analyzing the data, if the technical parameters are found to have exceeded the standard, an audible and visual alarm is immediately issued to alert the underground and uphole personnel. At the same time, the remote control means can also be used to activate gas lockout, wind power lockout, fault lockout and other protective measures, the underground coal mining machinery and equipment for power failure. Main environmental parameters sensor models and technical parameters, all sensors are intrinsically safe equipment, can adapt to the complex working environment of the mine.

V. Hardware support for coal mine safety monitoring systems

Positioning system application products:

Positioning Inventory Server WE-LS10

WiFi Network Card Reader Base Station WE-RWN03

Audible and visual reminder label WE-T56

Communications transmission system application hardware:

▲Environmental Monitoring Application Products R&D in...

VI. About Hainan Shidian

Hainan Shidian Technology Co., Ltd. to "make the standardization of industrial Internet of Things easier" as the vision, focusing on the direction of the Internet of Things industry chain, indoor positioning, sensing and control and data transmission products in the field of continuous research and development, Lego (Lego) production, precise to meet the small amount of industrial Internet of Things products and a variety of demand characteristics, to provide customer Complex environment and personalized needs to meet the real low inventory, high satisfaction of the new supply and demand relationship.

The company has four R&D centers in Shanghai, Suzhou, Chengdu and Taipei, adhering to the group's nearly 40 years of good business resources and reputation, firmly believe in the "be an expert in the industry" business philosophy, precise in the channel, sensitive to the market, focus on products, "research" is reliable, "production" is stable, "sales" is quality, always focusing on the industrial Internet of Things customers personalized scenarios to meet the ultimate needs. We believe in the business philosophy of "being an expert in the industry", we are precise in channels, sensitive to the market, and focus on products, "research" is reliable, "production" is stable, "sales" is quality, and we are always focusing on the ultimate satisfaction of personalized scenarios of industrial IoT customers.

In terms of products, we have both Zigbee positioning products, which have been cultivated by our self-research team for more than 10 years, and UWB positioning products, which are developed by our teams in Shanghai and Taipei, to meet the different needs of customers for positioning accuracy. At the same time, the company also introduces Bluetooth positioning products to supplement the self-developed solutions, in order to fully meet the needs of all kinds of customers.

Software support we integrate the overall program of various industries, actively open interfaces and source codes for system integrators to join, for related system software companies to do case demonstration based on our products to provide convenience, so that the Internet of Things indoor positioning applications broader.

Content Reviewer:Jimme Yao