I. Programmatic background

In the complex and crowded production environment of factories, efficient personnel management is crucial to improve production efficiency, ensure safe production and optimize resource allocation. Traditional management methods are difficult to accurately grasp the personnel location dynamics in real time, resulting in slow emergency response, unscientific task scheduling, etc. ZigBee positioning technology, with its long reading range, strong anti-interference, low power consumption, low rate, low cost and other characteristics, brings a new solution to the factory personnel positioning management, helping factories to realize intelligent and refined operation.

Second, the principle of ZigBee positioning technology

1. Principles of Positioning Technology

ZigBee technology transmits data by sending and receiving RSSI values, and utilizes the principle of signal strength value change in space for positioning. Multiple ZigBee base stations are deployed at different locations in the factory, personnel wear ZigBee positioning tags, the tags send signals to the surrounding base stations, the base stations receive the signals and calculate the distance between the tags and the base stations according to the change in signal strength and weakness, and then use the trilateration or polygonal measurement to determine the real-time location of the personnel in the factory, and the positioning accuracy can be up to 3-5 meters, which meets the demand of factory for the personnel's location and range awareness. The positioning accuracy can reach 3-5 meters, which can meet the demand of the factory for personnel location sensing.

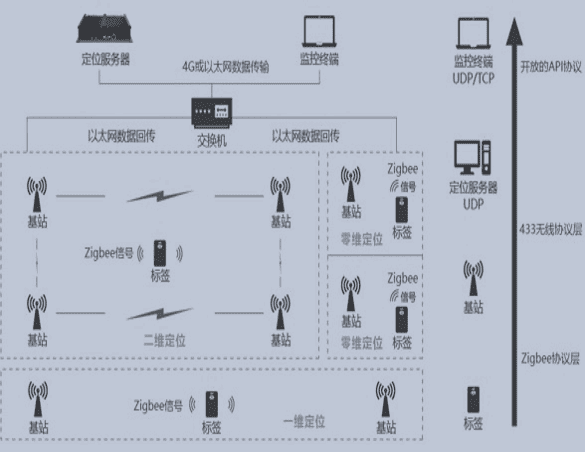

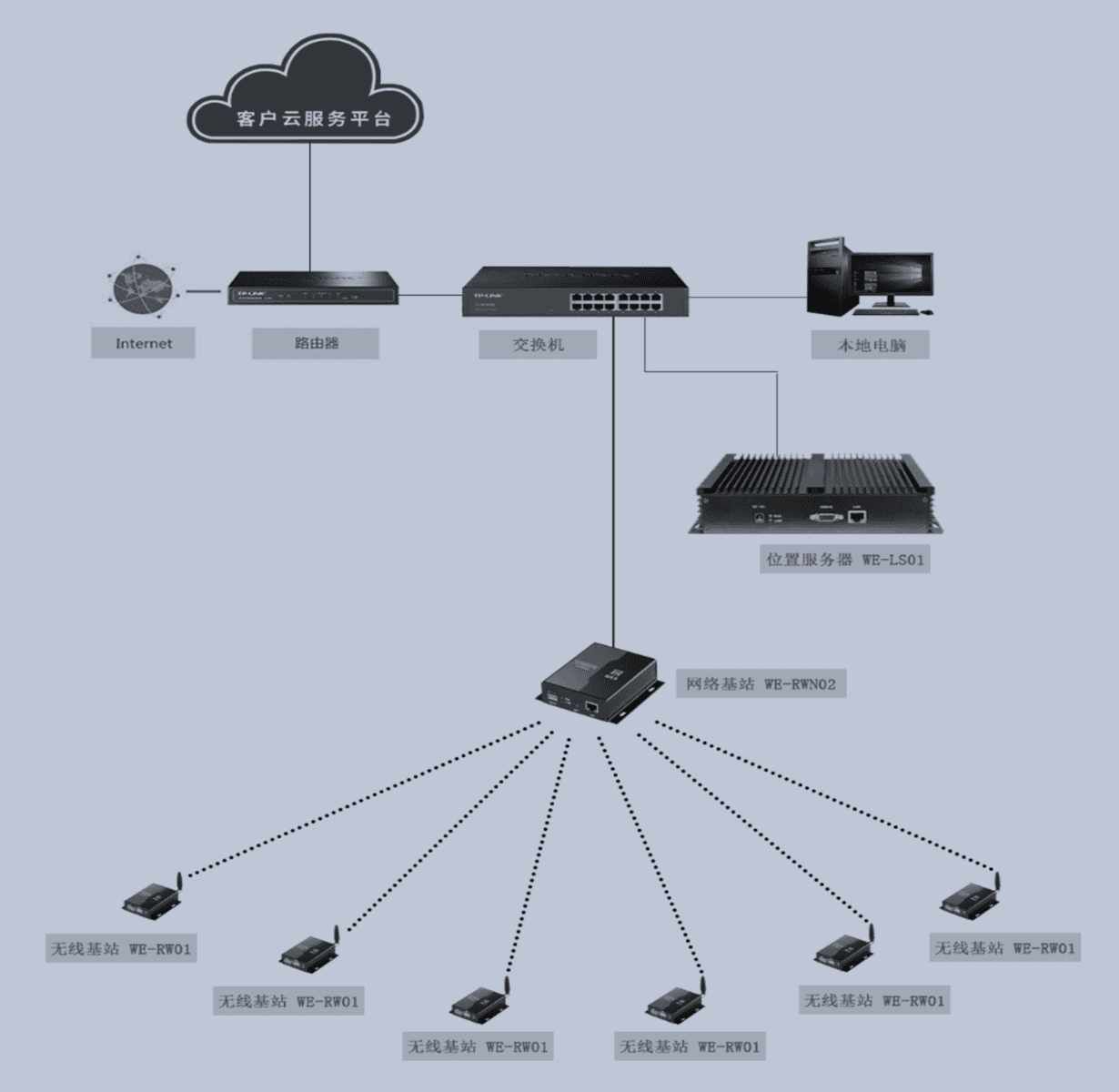

2. Network Topology Diagram

The 433MHz wireless network reader WE-RWN02 can be expanded by 15 wireless readers through the wireless network interface, including itself (the device itself is also a standalone reader) a wireless network can have up to 16 location base stations. Wireless reader will read the tag information reported to the wireless network reader, and then the wireless network reader will wireless network within the range of all the tag information reported to the location server, the location server to the data synthesis algorithm to derive the specific location of the tag.

III. System architecture

- location tag

Equip factory employees with lightweight, low-power ZigBee location tags, which can be worn as bracelets, badges and other forms to facilitate their daily work. The tags are waterproof, dustproof and shockproof to adapt to the harsh working environment of the factory. The tag sends out positioning signals at regular intervals, while the tag is equipped with SOS for emergency help, and the battery life ensures that it meets the needs of at least 2 years of continuous work. - ZigBee Base Station

According to the factory building layout and positioning accuracy requirements, ZigBee base stations are reasonably deployed in key areas such as workshops, warehouses and passages. The base station is connected to the positioning engine server through wired network, responsible for receiving tag signals and uploading data to the server in real time. The coverage area of the base station can be up to tens of meters, with strong signal penetration ability, which can effectively overcome the obstacles in the factory to block the signal and ensure the stability of the positioning signal. - Location Engine Server

As the core of the system, the positioning engine server runs the positioning algorithm, processes the tag signal data uploaded from the base station, and quickly and accurately calculates the personnel location coordinates. The server is also responsible for interfacing with existing information management systems (e.g. MES, ERP, etc.) in the factory to realize the fusion of personnel positioning data and production management data, and to provide data support for the upper-level applications. - Monitoring Management Platform

Presented in the form of Web or mobile APP, it provides managers with an intuitive and convenient operation interface. On the monitoring management platform, you can view the location distribution of all personnel in the factory in real time, conduct personnel track playback, set up electronic fences to realize regional access warning, generate personnel attendance reports, etc., to meet the needs of factory personnel management in an all-round way.

IV. Core equipment

⚡Tagged WE-T73

- Battery type: 2 x 7 alkaline batteries

- Wireless Transmission Power: 100mW

- Sending distance: 300 meters

- Operating band: 2.4GHz

- Working time: >3 years

- Protection class: IP67, rainproof

- Weight: 30G

- Working temperature: -20~60℃

- Overall dimensions: 63mm*45mm*24mm

⚡Wireless Base Station WE-RW02

- Simultaneous detection of tags: 200

- Detection distance open: 100 meters

- Transmit power: 30dBm

- Receiving sensitivity: -145dBm

- Wireless rate: 19200bps

- Extendable feeder length: 50 meters

- Wireless communication distance: 2000 meters

- Supply voltage: DC10V-DC26V

- Current consumption: 500mA (12V)

- Weight: 100g

- Size: 82mm × 103mm × 33mm

- Working Temperature: -40℃~+85℃

⚡Wireless Network Base Station WE-RWN02

- Simultaneous detection of tags: 500

- Detection distance open: 100 meters

- Wireless network interface: 16 wireless card readers

- Network port: 10M/100M adaptive

- Wireless Transmission Power: 30dBm

- Receiving sensitivity: -145dBm

- Wireless rate: 19200bps

- Extendable feeder length: 50 meters

- Wireless communication distance: 2000 meters

- Supply voltage: DC10V-DC26V

- Current consumption: 800mA (12V)

- Weight: 250g

- Size: 82mm × 103mm × 33mm

- Working Temperature: -40℃~+85℃

⚡Location Server WE-LS01

- CPU: Quad-core Cortex-A7 processor at 1.2GHz

- Memory: 1G RAM + 8G ROM

- Storage: 32GB

- Simultaneous detection of tags: 10000

- Simultaneous management of base stations: 500

- RS232 interface: 1 (debugging serial port)

- RS485 interface: 2

- Supply voltage: 9V-DC30V (wide voltage)

- Weight: 1500g

- Size: 234mm × 200mm × 52mm

- Working temperature: -20℃~+60℃

- Network port: 10M/100M adaptive

V. Functional realization

- Real-time location tracking

On the monitoring and management platform, managers can clearly see the real-time location of each employee, and differentiate different departments and work types of personnel with different color icons for quick identification. Through the map zoom, panning function, accurately view the distribution of personnel in a specific area, timely grasp of the personnel dynamics of the production site, to provide an accurate basis for production scheduling. - Trajectory playback analysis

The system automatically stores personnel historical track data and allows track playback based on time, personnel and other conditions. Through the playback function, managers can analyze employee work paths, assess the reasonableness of workflow, discover potential bottlenecks in productivity, optimize workflow, and improve overall productivity. - Electronic fence warning

On the monitoring and management platform, the electronic fence is drawn for dangerous areas and restricted access areas in the factory. When the positioning tags worn by personnel enter or leave the electronic fence area, the system immediately sends warning information to the management personnel to remind the relevant personnel to pay attention to the effective prevention of safety accidents, and safeguard the safe production of the factory. - Emergency help response

Employees who encounter emergencies at work can press the help button on the location tag. After the system receives the help signal, it immediately pops up an alarm prompt on the monitoring and management platform, displays the location information of the person seeking help, and at the same time sends SMS and pushes APP messages to the relevant person in charge to ensure that emergencies can be responded to and handled in a timely manner, and safeguard the life safety of employees. - Personnel attendance management

Utilizing the positioning system to record the arrival and departure time of employees and the length of stay in the work area, and automatically generating attendance reports. Compared with the traditional attendance method, ZigBee positioning attendance is more accurate and objective, avoiding the problems that may arise from manual attendance, such as punching the card on behalf of the card, omission of punching the card, reducing the workload of attendance management and improving the efficiency of attendance management.

VI. Implementation steps

- on-site investigation

The project team went deep into the factory to conduct a detailed survey of the factory building structure, personnel movement, production equipment layout, etc., and drew an accurate factory floor plan to provide a basis for the subsequent deployment of the base station and system parameter settings. - schematic design

Based on the results of the site survey, combined with the factory personnel management needs, develop a personalized ZigBee positioning system solution. Determine the number of base stations, installation locations, select the appropriate type of positioning tags, plan the system architecture and data transmission network, and ensure that the system meets the factory's requirements for positioning accuracy, coverage, and functional applications. - Equipment installation and commissioning

According to the design scheme, the installation of ZigBee base station, positioning tags and other equipment is carried out in the factory. After the installation is completed, the system is fully debugged to optimize the parameters of the base station to ensure that the tags communicate stably with the base station and the positioning accuracy meets the design requirements. At the same time, the positioning system and the factory's existing information management system for docking test, to ensure smooth data transmission. - Personnel training

Organize training for factory managers and relevant operators on the use of the system, so that they are familiar with the monitoring and management platform, location tag operation methods, and master the application of functions such as personnel positioning, track query, and early warning settings, to ensure that after the system is put into use, the relevant personnel will be able to use it proficiently. - System acceptance and optimization

After completing the system installation and debugging and personnel training, we organize the factory to accept the ZigBee positioning system. According to the problems found in the acceptance process, optimization and adjustment will be carried out in time to ensure stable and reliable operation of the system and meet the actual needs of factory personnel management.

VII. Analysis of benefits

- Enhance production efficiency

Through real-time location tracking and trajectory playback analysis, it optimizes the production process, reasonably schedules personnel, reduces personnel waiting time, and improves the efficiency of production collaboration, which is expected to increase the overall production efficiency of the factory 15%-20%. - Ensuring safe production

The electronic fence warning and emergency help response function effectively prevents security accidents, handles emergencies in a timely manner, reduces the incidence of accidents, protects the lives of employees, and reduces production interruptions and economic losses caused by security accidents. - Reduced management costs

Automated personnel attendance management, reducing the workload of manual attendance; accurate personnel positioning management, avoiding waste of resources, reducing management costs, is expected to save manpower and material costs of about 20%-30% per year. - Enhancement of enterprise competitiveness

The introduction of advanced ZigBee positioning technology realizes intelligent management of factory personnel, enhances the digital and intelligent level of the enterprise, strengthens the competitiveness of the enterprise in the industry, and lays the foundation for the long-term development of the enterprise.

Content Reviewer:Jimme Yao