Applications

Application of Normal Temperature and Normal Pressure Perfluorohexanone Jet Fire Extinguishing Device in Fire Extinguishing System for Large Wind Turbines

发表于 应用案例 |I. Product introduction of perfluorohexanone fire extinguishing agent

Perfluorohexanone (perfluoro-2-methyl-3-pentanone) fire extinguishing agent, at room temperature for the colorless, odorless transparent liquid, boiling point of about 49 ℃, latent heat of evaporation of water 1/25, very easy to vaporize. It has high extinguishing efficiency (comparable with Halon-1301), inactive to ozone (ODP=0), greenhouse effect index (GWP) is only 1, NOAEL is 10%, and good insulating properties.

Perfluorohexanone fire extinguishing agent has been applied in Europe and the United States and other developed countries for more than 20 years, and has been included in the standard of the National Fire Protection Association (NFPA2001 edition) as a clean gas fire extinguishing agent. Due to the superior performance of perfluorohexanone fire extinguishing agent, such as easy transportation, good compatibility, cleanliness and environmental protection, high extinguishing efficiency and low toxicity, it is considered to be the most promising fire extinguishing agent to replace halogenated alkanes such as sevofluoropropane and trifluoromethane and other transitional halogenated alkane fire extinguishing agents to date.

★ Principle of extinguishing perfluorohexanone fire extinguishing agent:

Perfluorohexanone fire extinguishing agent has a good fire extinguishing effect, its mechanism is through the physical and chemical aspects of the role of fire extinguishing, can be divided into three processes:

First: cooling fire: perfluorohexanone liquid sprayed at high speed atomization, vaporized by heat, due to the high heat capacity of vaporization, has a strong ability to absorb heat, so that the flame quickly lose heat, destroying the balance of the fire tetrahedron.

Second: asphyxiation: Perfluorohexanone has a high specific gravity, and in the process of suspension and falling, it can isolate the oxygen in the air around the flame.

Third: chemical suppression of fire extinguishing: free radicals of combustion chain reaction can be captured to terminate the chain reaction of flame propagation.

II. Product advantages of perfluorohexanone fire extinguishing agent

The application pain point problem of perfluorohexanone fire extinguishing agent and the company's solution idea.

At present, the mainstream perfluorohexanone fire extinguishing system at home and abroad, there is a big problem is the need to store perfluorohexanone fire extinguishing agent with high-pressure tanks, or through the pipeline system to complete the long-distance transmission of extinguishing agent, resulting in high cost of equipment, and due to the high-pressure problem, can not be used in special areas such as airplanes, warships, etc., and in the fields of big data server room, cultural relics protection field, high-pressure fire extinguishing system exists in damage to the object of protection. Risks.

In view of the pain points of the current application of perfluorohexanone fire extinguishing agent, the company's perfluorohexanone fire extinguishing device series of products, comprehensive implementation of the core points of the use of perfluorohexanone fire extinguishing agent at room temperature and atmospheric pressure, in the cost of the device, the use of safety, flexibility, and fire extinguishing effect, etc, has obvious advantages. The comprehensive and systematic application of normal temperature and normal pressure perfluorohexanone fire extinguishing product portfolio is suitable for fire extinguishing applications in enclosed and semi-enclosed spaces, as well as in small spaces.

Types of Perfluorohexanone Normal Temperature and Normal Pressure Fire Extinguishing Devices and Patent Applications of the Company

V. Causes of fires in large wind turbines and the current state of fire standards

Fire is mainly caused by man-made and non-man-made factors caused by fire, non-man-made factors are: generator cables and junction boxes, generator bearings overheating, high temperature of the brake system, lightning, generator winding short circuit, control cabinets, inverter cabinets, short circuit, etc.; man-made factors: improper maintenance, improper management, improper use of tools and equipment, and other factors.

WTG facilities and equipment are generally located in remote areas, high above ground, unmanned and far from rescue centers, and in the event of a fire, the loss is huge.

Every year, about 2~3‰ of wind turbines encounter fires, and the chance of fires in large WTGs is even higher, while many WTGs are still in the state of no automatic fire protection measures, so there is an urgent need to be equipped with automatic fire protection systems. At present, the automatic fire safety system for wind turbines is almost a blank, and there is an urgent need to study and implement cost-effective system technology, and prepare the corresponding specifications.

There is a virtual void in automatic fire safety systems for wind turbines, and there is an urgent need to research and implement cost-effective system technologies and prepare appropriate specifications.

VI. Overview of the program for large fan atmospheric pressure perfluorohexanone jet fire extinguishing system

Program overview

Large fan fire requirements, "early detection, early disposal" as the principle, with fiber-optic continuous temperature measurement system, with multi-parameter gas sensors and other different on-site sensors, the key protective parts of the cabin thermal runaway in the primary stage of the early stage of detection and early warning, the fire will be extinguished in the embryonic stage!

Normal temperature perfluorohexanone jet fire extinguishing device, by matching with the necessary on-site sensors, can realize the requirements of controllable jet application of perfluorohexanone with sufficient concentration and sufficient spraying time (amount) for on-site fire extinguishing in the nacelle of large wind turbines.

Key protection areas for large wind turbines

- Drive motors, control cabinets, power supply cabinets, etc. inside the hub;

- Inside the nacelle are generators, hydraulics, gearboxes, brakes, yaw drives, control cabinets, capacitor cabinets, connecting cables, etc;

- Converters, control cabinets, transformers, basic electrical cabinets, computer cabinets, etc. at the bottom of the tower

VII. Advantageous features of our large-scale fan fire-fighting program

- Accurate monitoring: bud state fire prediction, a variety of fire thermal runaway characteristics of the material online monitoring (continuous fiber optic temperature measurement, composite gas sensors, thermal cracking sensors, temperature sensors, smoke sensors, etc.), accurately perceive thermal runaway parts of the first fire danger point to do the pre-spraying of perfluorohexanone extinguishing agent, if the fire is still unable to control the spread of the fire, automatically enter the nacelle of a large fan fully submerged in the fire extinguishing process;

- Heat-absorbing cooling: Perfluorohexanone fire extinguishing agent is sprayed in sufficient quantity to extinguish the fire, and the fire equipment can be cooled down without damage;

- Inhibit thermal runaway: Perfluorohexanone fire extinguishing agent is electrically sprayed several times to inhibit thermal runaway;

- Customized nozzle system: Specialized infusion hose, quick couplings and customized nozzle combinations support quick installation with on-site cutting. Customized nozzles support rapid atomization to speed up fire extinguishing.

- The nozzle system can be installed to large wind turbine key fire warning units for flexible deployment. Combined with full nacelle submerged spray extinguishing agent, double insurance is achieved.

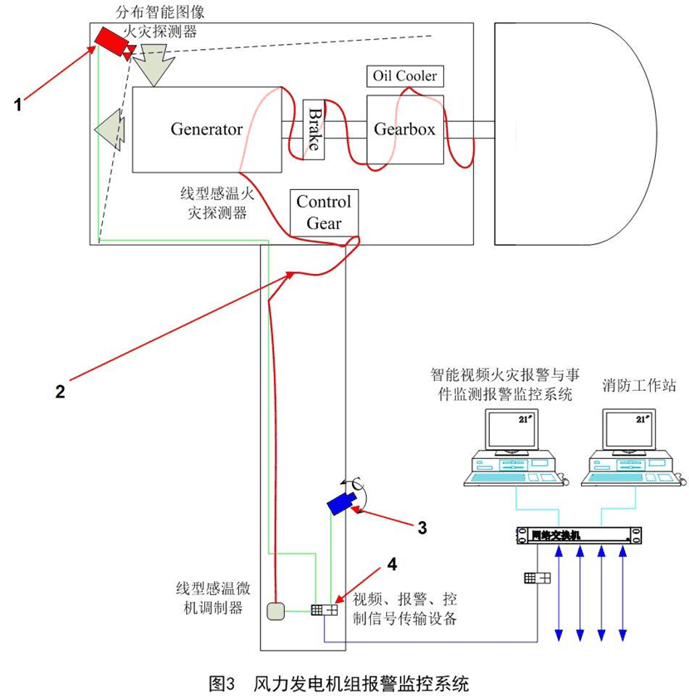

▲ Schematic diagram of the alarm system for a large-scale wind turbine fire protection scheme

A variety of fire thermal runaway characteristics of the material online monitoring sensors to choose from: image flame detector, continuous fiber optic temperature measurement, composite gas sensors, thermal cracking sensor, temperature sensors, smoke sensors and so on.

▼ Schematic diagram of a perfluorohexanone injection system for a large wind turbine fire protection program

Perfluorohexanone storage tanks at the bottom of multiple turbines are interconnected through a network of pipes to form a distributed storage system.

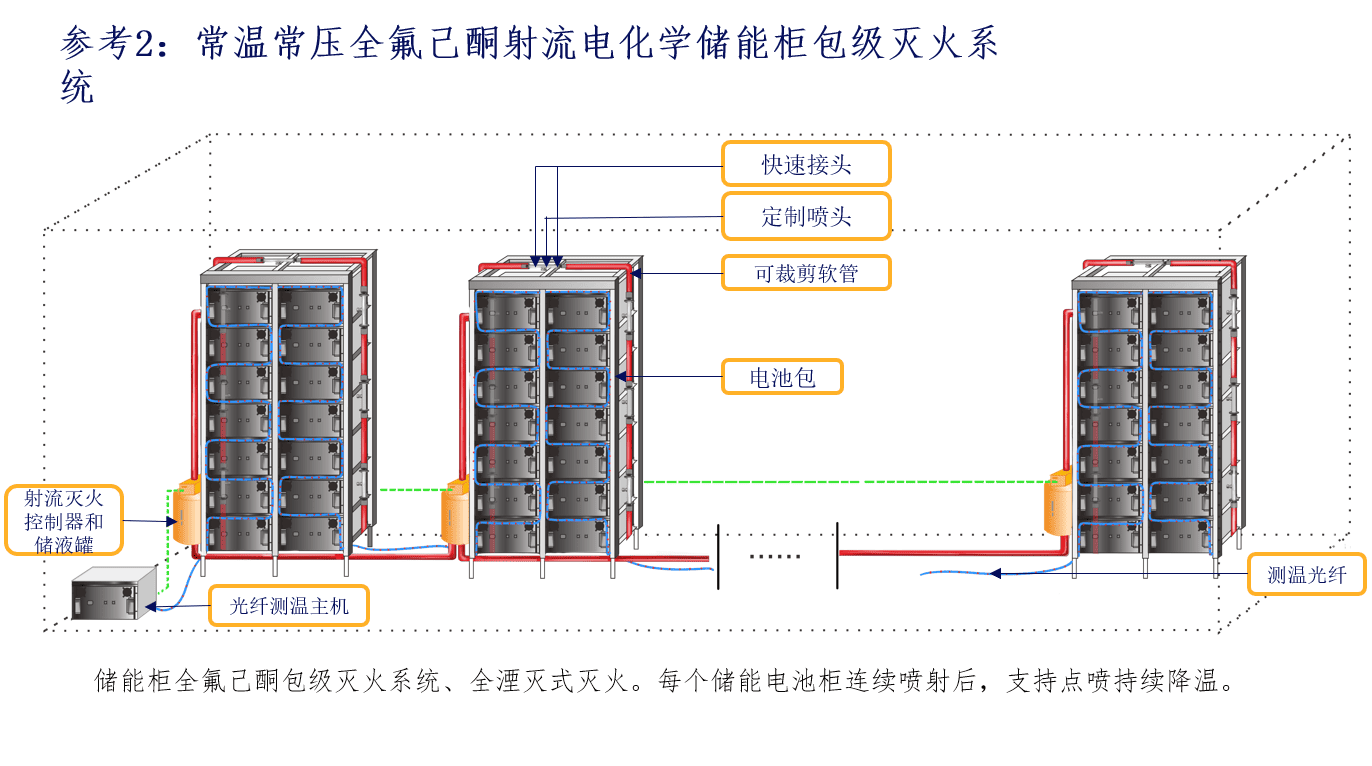

The following is a schematic diagram of a scheme for the application of ambient temperature and atmospheric pressure perfluorohexanone jet fire extinguishing systems in electrochemical storage cabinets. Case 1 is a fully immersed fire extinguishing system, and Scheme 2 is a packaged level fire extinguishing system, which is equivalent to each part of a large wind turbine that requires key protection, and a separate set of small, ambient temperature and atmospheric pressure perfluorohexanone jet extinguishing systems is deployed. Each system can be individually deployed sensors, can also share sensor information, continuous monitoring of fire suppression to determine whether to start the entire cabin of the submerged fire extinguishing system. This is the principle of realizing a dual-insurance fire suppression system.

Content Reviewer:Jimme Yao