i. program overview

China's current manufacturing industry, although the volume is huge, but the management is sloppy, not fine enough; although the government advocates "smart factory", "Industry 4.0" for many years, but the factory's level of intelligence is still very low, can not be compared with Germany, Japan and other manufacturing powerhouses. In addition to some large enterprises, such as Foxconn, Gree, in actively trying to factory robots, automated management, most of the small and medium-sized enterprises are still stuck in the comparative advantage of relying on labor cost advantage, the supply chain is relatively perfect survival. With the rise of China's new generation after 95, 00, the new generation has not satisfied with low pay + overtime pay system, coupled with the manufacturing industry back to the southeast industry and other lower-cost countries, China's manufacturing industry is facing the plight of the more aggravated. How to change the management problems of China's manufacturing factories and realize the transformation of manufacturing factories into "smart factories" and "intelligent factories"? This is a common problem in China's manufacturing industry.

II. Factories encountering difficulties

Due to the large number of people in the production workshop and its dispersion, it is impossible to control the production line staff in real time, and it is difficult to assess the on-duty situation quickly and to manage the situation of employees' crosstalk and off-duty; at present, the traditional manual supervision method is adopted, which is unable to effectively supervise and statistic the on-duty data. In order to better promote the intelligent construction and realize the fine management of the factory, the introduction of activeZigBee(used form a nominal expression)positioning technologyIn order to obtain the working hours invested by the employees in each position in the manufacturing process, the production capacity can be analyzed according to the production report at a later stage, thus optimizing the production structure and improving the production efficiency.

III. Programmatic structure

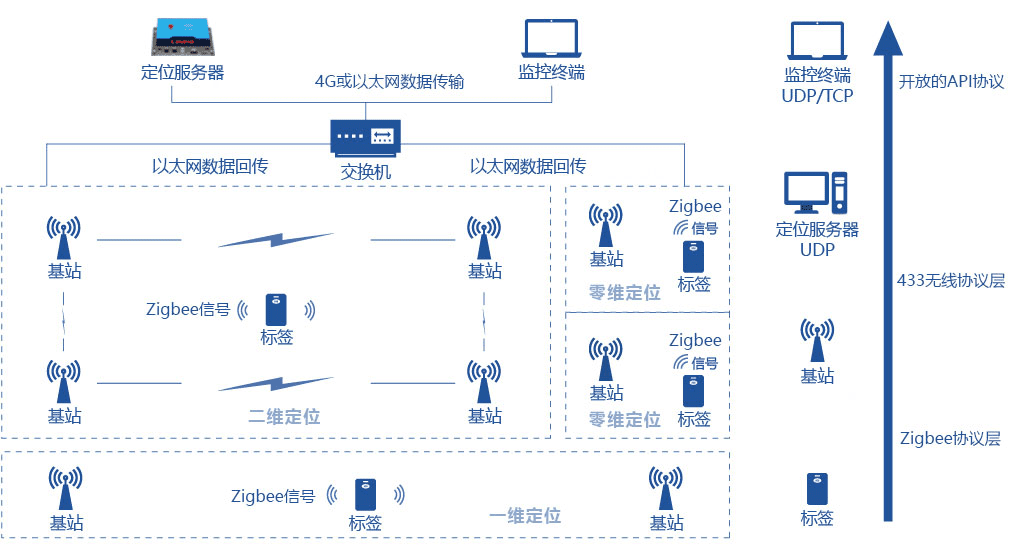

3.1 System architecture

Factory personnel positioning system mainly consists of 1: personnel carrying positioning tags; 2: receiving information positioning base station; 3: transmission and power supply network cable and DC power supply and switch; 4: positioning location server; 5: server computer and positioning software 5 parts. The positioning tag is responsible for sending the positioning pulse signal, the positioning base station is responsible for receiving the pulse signal and sending the information back to the location server through the network cable and switch, and the location server processes the positioning data and reports it to the positioning software on the server computer to display the positioning data in real time.

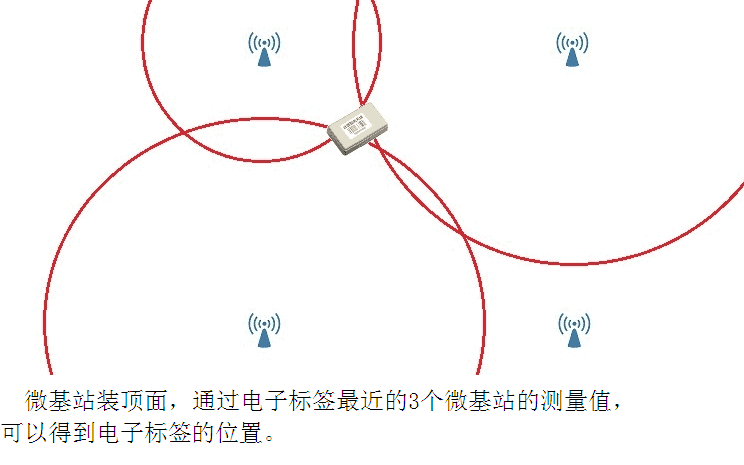

3.2 Three-Point Positioning Principle

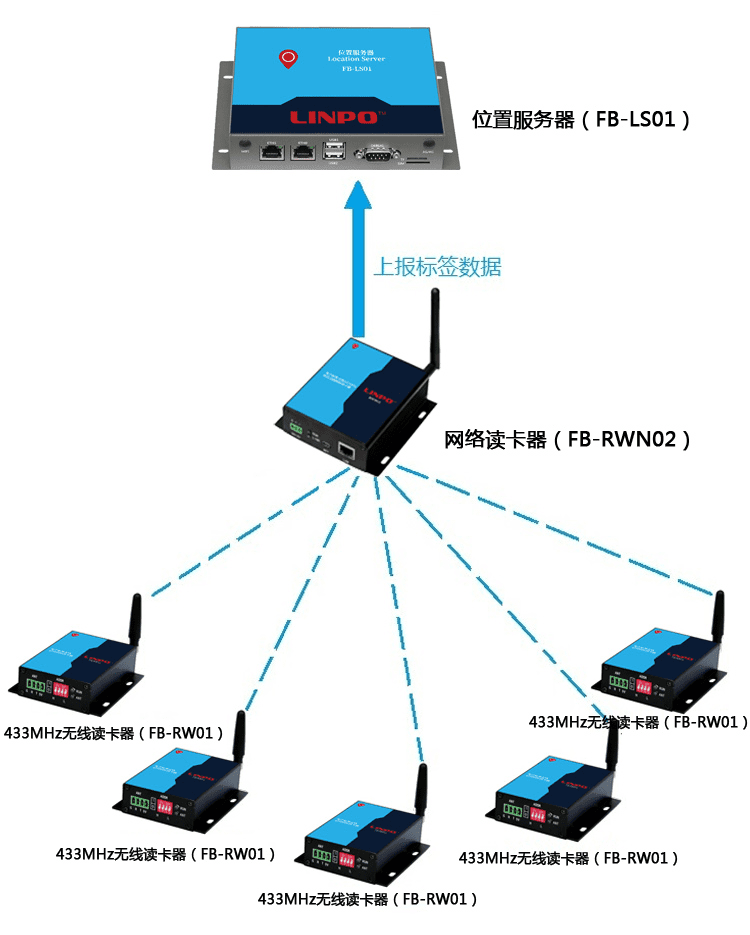

3.3 Network Topology

433MHz wireless network reader FB-RWN02 can be expanded through the wireless network interface 16 wireless readers, including themselves (the device itself is also an independent reader) a wireless network can have up to 17 location base stations. Wireless readers will read the tag information reported to the network reader, and then the network reader will wireless network range of all the tag information reported to the location server, the location server to the data synthesis algorithm to derive the specific location of the tag.

The location server has two Ethernet interfaces ETH0/ETH1. If the location base station is deployed to the user network, it is sufficient to use one interface ETH0, or you can build a new network for the location base station, which requires two Ethernet interfaces. It is recommended to build a new network for the positioning base station so that the operation of the positioning system will not be affected by the user's network and will be more stable.

IV. Demand realization

4.1 Program Matching Products

-

Electronic tag 433MHz wireless reader WE-RW02¥730

Electronic tag 433MHz wireless reader WE-RW02¥730 -

ZigBee long-distance range semi-active high-precision personnel positioning electronic tag WE-T28K125¥60

ZigBee long-distance range semi-active high-precision personnel positioning electronic tag WE-T28K125¥60 -

ZigBee125K Semi-Active High Precision Electronic Tag Low Frequency Activator WE-TX125¥688

ZigBee125K Semi-Active High Precision Electronic Tag Low Frequency Activator WE-TX125¥688 -

Badge WE-T32K electronic tags 2.4G active RFID radio frequency card ultra-thin waterproof roll-call attendance¥38

Badge WE-T32K electronic tags 2.4G active RFID radio frequency card ultra-thin waterproof roll-call attendance¥38 -

Long-distance range positioning electronic tag WE-T73¥66

Long-distance range positioning electronic tag WE-T73¥66 -

ZigBee Location Server WE-LS01¥4,339

ZigBee Location Server WE-LS01¥4,339 -

Active RFID 433 to Ethernet Network Reader WE-RWN02¥1,024

Active RFID 433 to Ethernet Network Reader WE-RWN02¥1,024 -

Electronic tag 433MHz wireless reader WE-RW01¥730

Electronic tag 433MHz wireless reader WE-RW01¥730 -

Long-distance range positioning electronic label WE-T28¥42

Long-distance range positioning electronic label WE-T28¥42 -

Object positioning replaceable battery tag WE-T22H¥52

Object positioning replaceable battery tag WE-T22H¥52

4.2 Label management

The tags are distributed according to the real-name binding system, one person, one tag. Before issuing the tags, you need to bind the tags with the designated operators on the platform, and enter the personnel information and operation contents.

When a tag is recalled, the associated information needs to be unbundled on the platform. This operation is not required for personnel who have been using the label for a long time in specific positions.

V. System functions

1、Real-time monitoring of factory workers to solve the difficult problem of workshop inspection

Through for the worker dispenses the electronic label card real-time locates to the factory where the workshop position, the administrative personnel may in the system background view different types personnel real-time position, is convenient the supervisory personnel at any time understands the different workshop different region personnel real-time state.

2、No perception of automatic clocking to solve the difficult problem of workers attendance

Every day when a worker enters the plant for the first time, it automatically records the worker's position as well as the time, and automatically generates an attendance record in the background. The real realization of non-perceptual automatic attendance.

3、Operation worker static alarm to solve the problem of worker laziness

The worker wears the electronic label to detect whether the worker is in a certain place to be still, when the still time exceeds the preset range, automatically sends the still alarm to the employee's superior leader, in order to prevent the worker's lazy behavior.

4、Hazardous area alarms to solve the problem of accident-prone hazardous areas in the factory area.

Shidian Technology personnel positioning system with customized fence area setting function, when set up the virtual electronic fence, when the workers enter the electronic fence immediately send alarm information to the background system, convenient for factory management personnel to understand the first time what people enter the factory's dangerous areas.

VI. System features and advantages

- positioning accuracy: Average accuracy of 3-5m;

- Longer reach: Visual coverage distance 30-100m;

- More Flexible Networking: Wired Stabilization Network;

- Free client software, manage tags, locate base stations, and view real-time location of tags.

- Open Management AgreementThe company has fully integrated the positioning function into its own system platform.

- Send UDP location data externally, facilitate system integration. Support deep customization development.

Content review.